Rapid Prototyping

Overview

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data. The use of rapid prototyping techniques is prominent in sectors such as manufacturing, automotive, aerospace, medical, and industrial design. Rapid prototyping allows designers and engineers to create prototypes quickly and efficiently, allowing for faster iteration and improvement of designs.

History

The concept of rapid prototyping as a method for creating physical objects was first proposed by Japanese researcher Dr. Hideo Kodama in 1981. He developed a system that used ultraviolet lights to harden polymers and create solid objects. However, it was not until 1987 that the first commercially available rapid prototyping system, known as Stereolithography Apparatus (SLA), was developed by Chuck Hull, the co-founder of 3D Systems Corporation 3D Systems Corporation.

Techniques

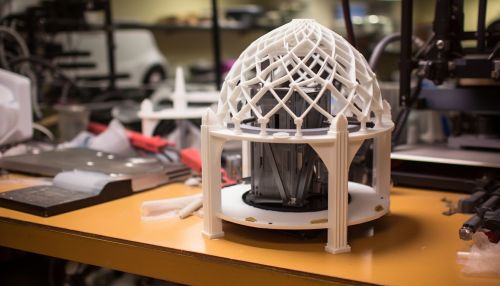

There are several techniques used in rapid prototyping, each with its own advantages and disadvantages. These include:

Stereolithography (SLA)

Stereolithography is a rapid prototyping process which employs a vat of liquid ultraviolet curable photopolymer resin and an ultraviolet laser to build parts' layers one at a time.

Selective Laser Sintering (SLS)

Selective Laser Sintering is another method of rapid prototyping that uses a high power laser to fuse small particles of plastic, metal, ceramic, or glass powders into a mass representing a desired 3D object.

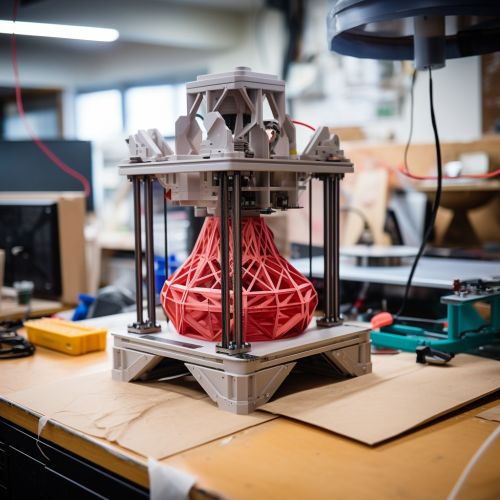

Fused Deposition Modeling (FDM)

Fused Deposition Modeling is an additive manufacturing technology commonly used for modeling, prototyping, and production applications. It is one of the techniques used for 3D printing.

Digital Light Processing (DLP)

Digital Light Processing is a similar process to stereolithography in that it works with photopolymers. The major difference is the light source. DLP uses a more conventional light source, such as an arc lamp, with a liquid crystal display panel or a deformable mirror device (DMD), which is applied to the entire surface of the vat of photopolymer resin in a single pass, generally making it faster than SLA.

Applications

Rapid prototyping is used in a wide range of industries. Its primary use is to create prototypes for product development efforts in industries such as aerospace, automotive, and electronics. It is also used in the medical industry to create detailed anatomical models for surgical preparation. In the field of industrial design, rapid prototyping is used for concept visualization and form studies.

Benefits and Limitations

Rapid prototyping offers numerous benefits, including a reduction in project cost and risk, the ability to customize products, and a faster time to market. However, it also has its limitations, such as the potential for design dependency and a lack of robustness in some techniques.

Future Developments

The future of rapid prototyping is likely to be influenced by advances in materials science, process technology, and system integration. As these technologies continue to evolve, the speed, accuracy, and range of materials that can be used in rapid prototyping are expected to increase.