Stereolithography

Introduction

Stereolithography (SLA) is a form of 3D printing technology used for creating models, prototypes, patterns, and production parts in a layer by layer fashion using photopolymerization, a process by which light causes chains of molecules to link together, forming polymers. This technique was first introduced in 1986 by Chuck Hull, who also founded the company 3D Systems to commercialize it.

History

The concept of stereolithography was first patented by Chuck Hull in 1986. Hull's patent described a concentrated beam of ultraviolet light focused onto the surface of a vat filled with liquid photopolymer. The light beam draws the object layer by layer, and after each layer is drawn, the platform in the vat steps down one layer in thickness. This process continues until the entire object is built.

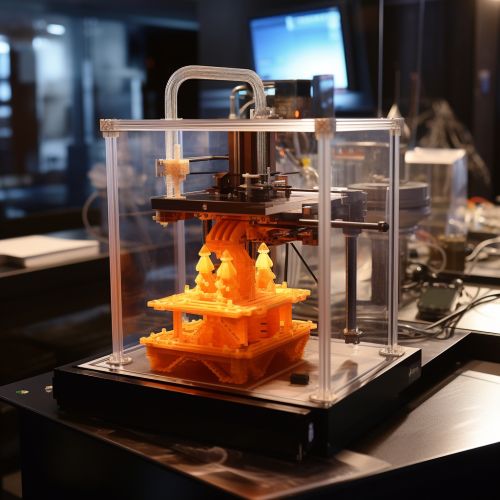

Process

The stereolithography process takes place in a large tank and begins with a layer of liquid photopolymer spread over a platform. Once the photopolymer layer is spread, the machine uses a UV laser to draw the first layer of the object onto the surface of the liquid. The UV light cures, or hardens, the photopolymer, bonding it to the layer beneath. This process is repeated layer by layer until the entire object has been built.

Materials

The materials used in stereolithography are photosensitive thermoset polymers that come in a liquid form. When exposed to a specific light wavelength, usually ultraviolet light, these polymers react and form cross-links, hardening into a solid structure. The properties of the final product depend largely on the type of polymer used, which can be adjusted to achieve specific characteristics such as flexibility, transparency, or resistance to heat and chemicals.

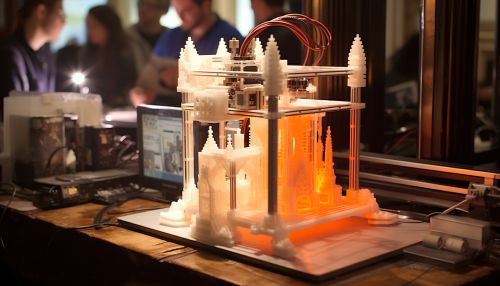

Applications

Stereolithography is used in a wide range of industries including automotive, aerospace, medical, dental, and consumer goods. It is commonly used for prototyping, as it allows designers to quickly produce complex shapes that would be difficult or impossible to create with traditional manufacturing methods. In addition, it is increasingly being used for production of end-use parts, particularly in the medical and dental industries where customization is often required.

Advantages and Disadvantages

The main advantage of stereolithography is its ability to produce parts with high accuracy and good surface finish. It can also produce complex geometries that are not possible with other manufacturing methods. However, the process is relatively slow compared to other 3D printing technologies, and the materials used are often not as strong or durable as those used in traditional manufacturing methods. Additionally, parts produced by stereolithography are often brittle and may degrade over time when exposed to sunlight.

Future Developments

The future of stereolithography is likely to be influenced by advances in materials science and improvements in the speed and accuracy of the technology. Researchers are currently exploring the use of new materials, including ceramics and metals, which could expand the range of applications for stereolithography. In addition, advances in software and hardware are expected to increase the speed and reduce the cost of the process, making it more accessible for a wider range of applications.