3D Printing

Introduction

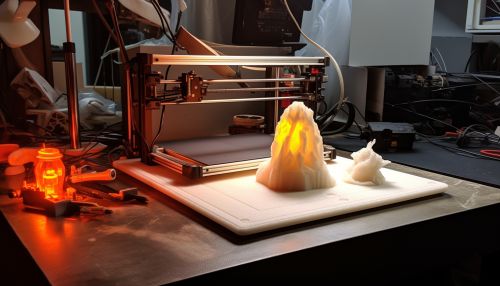

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. The creation of a 3D printed object is achieved using additive processes, where an object is created by laying down successive layers of material until the object is complete. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object learn more.

History of 3D Printing

The history of 3D printing dates back to the 1980s. Chuck Hull invented the first 3D printing process called 'stereolithography' in 1983 learn more. He also founded the company 3D Systems to commercialize the technology. In the following years, other 3D printing technologies such as Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS) were developed learn more learn more.

3D Printing Technologies

There are several types of 3D printing technologies available today. The most common ones include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each technology has its own strengths and weaknesses, and is suitable for different applications.

Fused Deposition Modeling (FDM)

FDM is the most commonly used 3D printing technology. It works by extruding a thermoplastic material layer by layer to build up a 3D object. The material is heated until it melts and is then extruded through a nozzle, where it cools and solidifies to form a solid object.

Stereolithography (SLA)

SLA is a 3D printing technology that uses a laser to cure a photopolymer resin, layer by layer. The laser is used to draw a cross-section of the object onto the surface of the liquid resin, which hardens where it is struck by the laser. The object is then built up layer by layer.

Selective Laser Sintering (SLS)

SLS is a 3D printing technology that uses a laser to sinter powdered material, layer by layer. The laser is used to draw a cross-section of the object onto the surface of the powder, which fuses the particles together to form a solid object. The object is then built up layer by layer.

Applications of 3D Printing

3D printing has a wide range of applications across various industries. These include prototyping, product development, medical applications, architecture, and even food production.

Prototyping

3D printing is widely used for prototyping. It allows designers to create a physical model of their design, which can be used for testing and evaluation. This can significantly reduce the time and cost of the design process.

Product Development

3D printing is also used in product development. It allows companies to create a physical prototype of a new product before it goes into mass production. This can help to identify any design flaws or issues that need to be addressed before the product is manufactured on a large scale.

Medical Applications

3D printing has numerous applications in the medical field. These include the production of custom prosthetics, dental implants, and even bio-printing of human tissues and organs learn more.

Architecture

In architecture, 3D printing is used to create detailed scale models of architectural designs. It can also be used to produce components for actual buildings.

Food Production

3D printing is also being explored in the field of food production. It has the potential to create complex shapes and structures from edible materials, opening up new possibilities for food design and presentation.

Future of 3D Printing

The future of 3D printing looks promising, with advances in technology and materials expected to drive further adoption of the technology. Some of the potential future developments in 3D printing include improvements in speed and accuracy, the ability to print with a wider range of materials, and the potential for large-scale industrial applications.