Yield Monitor

Introduction

A yield monitor is an electronic device that is integrated into modern agricultural machinery, particularly combine harvesters, to measure the amount of crop that is being harvested at any given location and time. This device is a key component in precision agriculture, a farming management concept that uses technology to optimize returns on inputs while preserving resources.

History and Development

The concept of yield monitoring was first introduced in the late 20th century, with the first commercial yield monitors being available in the early 1990s. The development of yield monitors was driven by the need for more precise and detailed information about crop yields to improve farm management decisions. Early yield monitors were relatively simple devices that used grain flow sensors and ground speed sensors to estimate yield. Over time, yield monitors have become more sophisticated, incorporating additional sensors and integrating with other technologies such as GPS and GIS to provide more accurate and detailed yield data.

Components and Functioning

A yield monitor consists of several key components:

- Grain Flow Sensor: This sensor measures the mass flow rate of the grain entering the combine. It is typically located at the top of the clean grain elevator.

- Moisture Sensor: This sensor measures the moisture content of the grain. It is important for adjusting yield data for moisture content, as grain yield is usually reported at a standard moisture level.

- Ground Speed Sensor: This sensor measures the speed of the combine. It is used to adjust the yield data for the area harvested per unit time.

- Header Position Sensor: This sensor measures the height of the combine header above the ground. It is used to determine when the combine is harvesting crop and when it is not.

- GPS Receiver: This device receives signals from GPS satellites to determine the precise location of the combine. It is used to georeference the yield data, allowing the creation of yield maps.

The yield monitor works by continuously measuring the flow of grain into the combine and the speed of the combine. It then calculates the yield (usually in bushels per acre or tons per hectare) by dividing the grain flow by the area harvested. This yield data is then georeferenced using the GPS data and stored for later analysis.

Applications and Benefits

Yield monitors have several applications in precision agriculture:

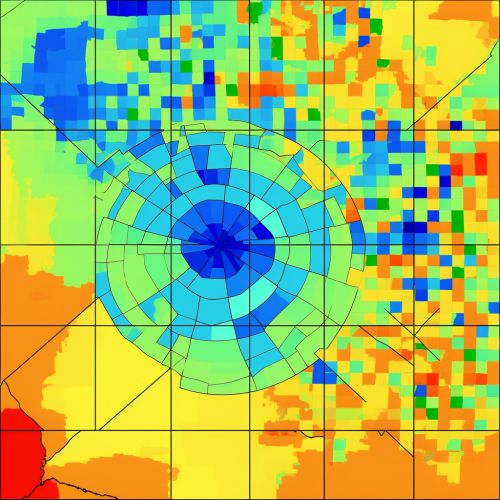

- Yield Mapping: Yield monitors, in combination with GPS and GIS, allow the creation of yield maps. These maps show the spatial variability of yield within a field, helping farmers identify areas of high and low productivity.

- Variable Rate Technology: Yield data from yield monitors can be used to develop variable rate application maps for inputs such as fertilizers and pesticides. This can help optimize input use, reducing costs and environmental impacts.

- Crop Management: Yield data can help farmers make better decisions about crop management, such as choosing the best varieties, optimizing planting dates, and managing pests and diseases.

- Research and Extension: Yield monitors are also used in agricultural research and extension to evaluate the effects of different management practices on yield.

The use of yield monitors can provide several benefits to farmers:

- Increased Profitability: By providing detailed information about yield variability, yield monitors can help farmers make better management decisions, potentially increasing profitability.

- Improved Sustainability: By enabling more precise application of inputs, yield monitors can help reduce environmental impacts and improve the sustainability of farming operations.

- Enhanced Knowledge: Yield monitors can help farmers gain a better understanding of their fields and the factors affecting yield, enhancing their ability to manage their crops effectively.

Challenges and Limitations

While yield monitors offer many benefits, they also have some challenges and limitations:

- Data Quality: The accuracy of yield monitors depends on the quality of the data they collect. Factors such as sensor calibration, combine speed variability, and grain moisture variability can affect data quality.

- Data Interpretation: Interpreting yield data can be complex, as yield variability can be influenced by many factors, including soil properties, weather conditions, and management practices.

- Data Management: Yield monitors generate large amounts of data, which can be challenging to manage and analyze.

- Cost: Yield monitors and associated technologies (e.g., GPS and GIS) can be expensive, which may be a barrier for some farmers.

Despite these challenges, the use of yield monitors is becoming increasingly common in modern agriculture, and ongoing technological advancements are likely to further enhance their capabilities and benefits.

Future Trends

The future of yield monitoring is likely to be influenced by several trends:

- Integration with Other Technologies: Yield monitors are increasingly being integrated with other technologies, such as crop sensors, drones, and machine learning algorithms, to provide more detailed and accurate information about crop conditions and yield.

- Automation and Robotics: As farming becomes more automated, yield monitors will play a key role in enabling precision agriculture technologies such as autonomous tractors and variable rate technology.

- Data Sharing and Analysis: Advances in data sharing and analysis technologies are making it easier for farmers to manage and interpret yield data, enabling more informed decision-making.

- Sustainability and Traceability: As consumers and regulators demand more sustainable and traceable food production, yield monitors will be important tools for demonstrating compliance with these demands.