The Role of Nanoscale Surface Engineering in Material Science

Introduction

Nanoscale surface engineering, a subfield of material science, plays a pivotal role in the development and optimization of materials with enhanced properties. The process involves the manipulation of the surface properties of materials at the nanoscale, which is typically between 1 and 100 nanometers. The ability to control and modify the surface properties of materials at this scale has led to significant advancements in various fields, including electronics, medicine, energy, and environmental science.

Nanoscale Surface Engineering Techniques

There are several techniques used in nanoscale surface engineering, each with its unique advantages and applications. These techniques include atomic layer deposition, chemical vapor deposition, physical vapor deposition, and self-assembled monolayers.

Atomic Layer Deposition

Atomic layer deposition (ALD) is a thin film deposition technique that uses a sequential, self-limiting process to create nanoscale films. The process involves the alternate pulsing of precursor gases into a reaction chamber, allowing for precise control over film thickness and composition. ALD is widely used in the semiconductor industry for the fabrication of nanoscale devices.

Chemical Vapor Deposition

Chemical vapor deposition (CVD) is another thin film deposition technique that involves the chemical reaction of gaseous precursors on a heated substrate to form a solid film. CVD is commonly used in the production of high-performance materials, such as diamond-like carbon and silicon carbide, due to its ability to produce films with excellent hardness, wear resistance, and thermal stability.

Physical Vapor Deposition

Physical vapor deposition (PVD) is a process that involves the evaporation or sputtering of a material, followed by its condensation onto a substrate. PVD is widely used in the manufacturing of electronic components and optical devices, due to its ability to produce thin films with high purity and uniformity.

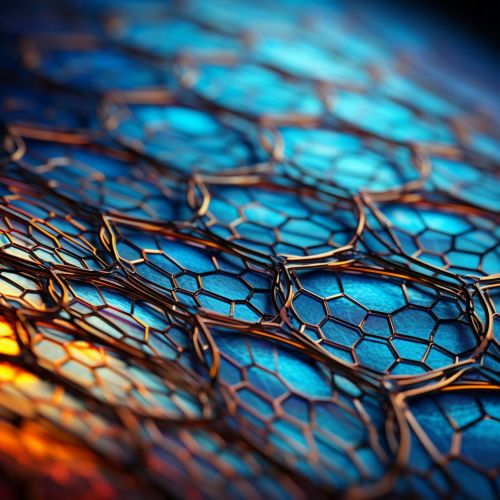

Self-Assembled Monolayers

Self-assembled monolayers (SAMs) are assemblies of molecules that spontaneously organize themselves into a monolayer on a substrate. SAMs are used in a variety of applications, including the fabrication of biosensors and the modification of surface properties, such as wettability and adhesion.

Applications of Nanoscale Surface Engineering

Nanoscale surface engineering has a wide range of applications, owing to its ability to enhance the properties of materials and create new functionalities.

Electronics

In the field of electronics, nanoscale surface engineering is used in the fabrication of semiconductor devices, such as transistors and diodes. The ability to control the thickness and composition of thin films at the nanoscale allows for the creation of devices with improved performance and reduced size.

Medicine

In medicine, nanoscale surface engineering is used in the development of drug delivery systems and biosensors. The modification of surface properties at the nanoscale can improve the targeting and delivery of drugs, as well as the sensitivity and selectivity of biosensors.

Energy

In the energy sector, nanoscale surface engineering is used in the fabrication of solar cells and fuel cells. The ability to engineer surfaces at the nanoscale can enhance the efficiency of these devices by improving light absorption and charge transport.

Environmental Science

In environmental science, nanoscale surface engineering is used in the development of catalysts for pollution control and water purification. The modification of surface properties at the nanoscale can enhance the activity and selectivity of catalysts, as well as the efficiency of water purification systems.

Conclusion

Nanoscale surface engineering is a powerful tool in material science, enabling the development of materials with enhanced properties and new functionalities. The ability to control and modify the surface properties of materials at the nanoscale has opened up new possibilities in various fields, from electronics and medicine to energy and environmental science. As our understanding of nanoscale phenomena continues to grow, so too will the potential applications of nanoscale surface engineering.