Supervisory Control and Data Acquisition

Introduction

Supervisory Control and Data Acquisition (SCADA) is a complex system composed of both software and hardware components. These components work in unison to enable industrial organizations to control industrial processes either on-site or at remote locations. SCADA systems also facilitate the monitoring, gathering, and processing of real-time data. They allow direct interaction with devices such as sensors, valves, pumps, motors, and more through Human-Machine Interface (HMI) software. Furthermore, these systems are capable of recording events into a log file.

SCADA systems play a crucial role in industrial organizations as they aid in maintaining efficiency, processing data for informed decision-making, and communicating system issues to help mitigate downtime.

History

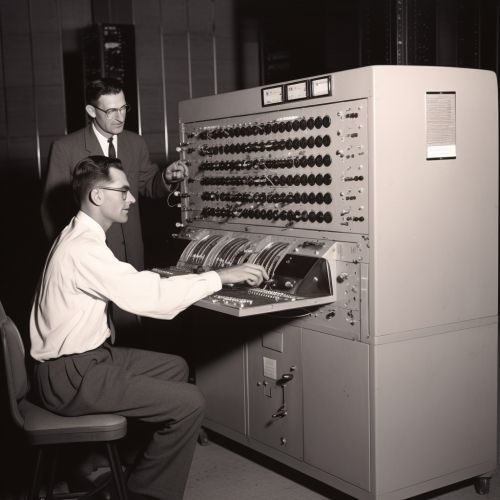

The origins of SCADA can be traced back to the 1950s when telemetry was initially utilized to control and monitor systems. However, the term 'SCADA' itself was not coined until the 1970s. The evolution of SCADA systems has been parallel to the growth of distributed computing systems. Early SCADA systems made use of mainframe computers, a single central processor, to oversee all operations. In contrast, modern SCADA systems are predominantly distributed systems with distributed processing.

Architecture

A SCADA system is composed of several interconnected components that collectively form a complete system. These components include:

- Human-Machine Interface (HMI)

- Supervisory System

- Remote Terminal Units (RTUs)

- Programmable Logic Controllers (PLCs)

- Communication Infrastructure

The HMI is a device or software that allows operators to control the SCADA system. The supervisory system is responsible for data collection on the process and dispatching commands to the field devices. RTUs and PLCs are devices that interface with the field devices and convert sensor signals into digital data. The communication infrastructure connects the supervisory systems to the RTUs.

Applications

SCADA systems find application in numerous industries to monitor and control industrial processes. Some of the key industries include:

- Power Generation, Transmission, and Distribution

- Water and Waste Control

- Building, Facility and Process Control

- Manufacturing

- Mass Transit

- Traffic Signals

- Oil and Gas Refining

- Telecommunications

Security

SCADA systems, due to their connectivity, are potentially vulnerable to cyber attacks. Therefore, the security of SCADA-based systems has been a concern as these systems are increasingly connected to the internet for operational efficiency. Appropriate cybersecurity measures need to be implemented to safeguard SCADA systems from cyber threats.

Future Trends

The future of SCADA is anticipated to be shaped by the integration of advanced technologies such as the Internet of Things (IoT), cloud computing, and machine learning. These technologies are expected to enable more efficient data processing, predictive maintenance, and overall operational efficiency.