Pump

Introduction

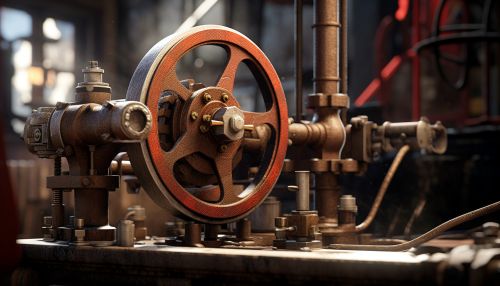

A pump is a mechanical device that moves fluids, such as liquids, gases or slurries, by mechanical action. Pumps can be classified into three major groups according to the method they use to move the fluid: direct lift, displacement, and gravity pumps[1].

Types of Pumps

Pumps operate by some mechanism (typically reciprocating or rotary), and consume energy to perform mechanical work moving the fluid. Pumps operate via many energy sources, including manual operation, electricity, engines, or wind power, and come in many sizes, from microscopic for use in medical applications to large industrial pumps.

Mechanical Pumps

Mechanical pumps serve in a wide range of applications such as pumping water from wells, aquarium filtering, pond filtering and aeration, in the car industry for water-cooling and fuel injection, in the energy industry for pumping oil and natural gas or for operating cooling towers. In the medical industry, pumps are used for biochemical processes in developing and manufacturing medicine, and as artificial replacements for body parts, in particular the artificial heart and penile prosthesis.

Reciprocating Pumps

A reciprocating pump is a class of positive-displacement pumps which includes the piston pump, plunger pump and diaphragm pump. When well maintained, reciprocating pumps will last for years or even decades; however, left untouched, they can undergo rigorous wear and tear[2].

Rotary Pumps

Rotary pumps are a type of positive displacement pump that use rotation to move fluid. They are efficient and reliable and can handle a wide range of viscosities. There are four basic types of rotary pumps: gear pumps, screw pumps, moving vane pumps, and circumferential piston pumps[3].

Electromagnetic Pumps

Electromagnetic pumps are a type of pump that use magnetic fields to generate pump action. These are typically used in high flow rate applications, such as cooling systems in nuclear reactors[4].

Gravity Pumps

Gravity pumps include the syphon and the hydraulic ram. These pumps function by using the kinetic energy of water and the force of gravity to create pressure and move water. They are typically used in situations where power is not available, or is too expensive to install and maintain[5].

Pump Performance

The performance of a pump is usually represented by a chart known as the pump characteristic curve. This curve shows the relationship between the flow rate (Q) and the total head (H) of the pump. Other important performance parameters include power (P), efficiency (η), and NPSH (Net Positive Suction Head)[6].

Pump Selection

The selection of a pump is based on several factors, including the system characteristics, the type of fluid to be pumped, the capacity, the total differential head, and the NPSH available. The pump selection process involves the evaluation of these factors to determine the most suitable pump for a specific application[7].

Pump Maintenance

Regular maintenance of pumps is crucial to ensure their efficient operation and longevity. Maintenance activities include regular inspection, cleaning, lubrication, and replacement of worn parts. Proper maintenance can prevent pump failure, reduce downtime, and increase the life of the pump[8].