Microfabrication

Introduction

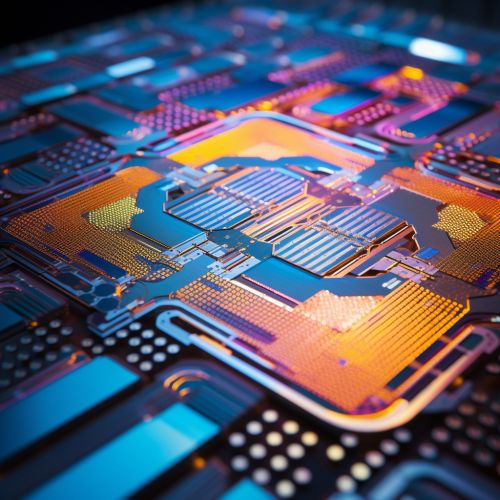

Microfabrication is the process of fabricating miniature structures of micrometre scales and smaller. Historically, the earliest microfabrication processes were used for integrated circuit fabrication, also known as "semiconductor manufacturing" or "semiconductor device fabrication". In the last two decades microelectromechanical systems (MEMS), microsystems (European usage), micromachines (Japanese terminology) and their derivatives have re-used, adapted or extended microfabrication methods. Flat-panel displays and solar cells are also using similar techniques.

History

Its origins can be traced back to the 1960s when the miniaturization of electronic devices became a necessity for getting more computing power into smaller spaces, leading to the birth of the integrated circuit. This has led to the displacement of earlier electronics technologies, such as vacuum tube and discrete transistor electronics, with integrated electronics.

Materials

Microfabrication technologies originate from the microelectronics industry, and the devices are usually made on silicon wafers. Even though these technologies are generally more expensive than traditional mechanical machining techniques, they allow for much higher precision, and in many cases are more economical for small quantities of parts. Even though most microfabrication processes are applied to silicon, it is also possible to use other materials. For instance, it is possible to perform lithography on polymers other than silicon, and metals can be patterned by lift-off. Glass and quartz are also common substrates in microfabrication.

Processes

Microfabrication is actually a collection of technologies which are utilized in making microdevices. Some of them have very old origins, not connected to electronics, like soft lithography, molding, printing (inkjet print), blow molding, etc. Some of the traditional techniques are also used, like machining, grinding, wire bonding, die attach, etc. but specially adapted to small scales and special needs of microdevices.

Photolithography

Photolithography is an optical means for transferring patterns onto a substrate. It is a crucial process in microfabrication. The process uses light to transfer a geometric pattern from a photomask to a photosensitive chemical, or photoresist on the substrate. This procedure is comparable to traditional photography.

Etching

Etching is the process where unwanted parts of films are removed by the chemical reaction with etchants. They react with the material being etched, resolve it, and then the reaction products are removed by the liquid or gaseous etchant. There are two types of etching processes: Wet etching and dry etching.

Thin films

Thin films are layers of material deposited onto a substrate. The films could range from fractions of a nanometer to several micrometers in thickness. These films are central to the manufacture of electronic components, as they can modify the properties of the materials used in the components.

Applications

Microfabrication is used to manufacture MEMS, silicon photonics, lab on a chip devices, microfluidic devices, and is also used in other branches of technology.

See Also

- Semiconductor device fabrication

- Microelectromechanical systems

- Silicon photonics

- Lab on a chip

- Microfluidics