Microelectromechanical systems

Introduction

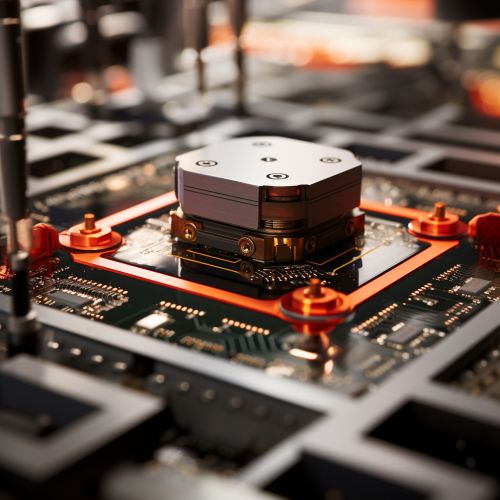

Microelectromechanical systems (MEMS) are miniaturized mechanical and electro-mechanical elements (i.e., devices and structures) that are made using the techniques of microfabrication. The critical physical dimensions of MEMS devices can vary from well below one micron on the lower end of the dimensional spectrum, all the way to several millimeters. Likewise, the types of MEMS devices can vary from relatively simple structures having no moving elements, to extremely complex electromechanical systems with multiple moving elements under the control of integrated microelectronics.

History

The idea of MEMS originated around the mid-20th century, however, the actual manufacturing of MEMS became possible in the 1980s with the development of industrial processes such as photolithography, etching, and micro molding. These processes allowed for the production of mechanical parts on the micro scale, which were then combined with electronic components to create MEMS.

Design and Fabrication

The design and fabrication of MEMS involves a specialized process called microfabrication. This process, which is also used in the manufacturing of integrated circuits, uses a combination of photolithography and etching to create the mechanical components of MEMS. The electronic components of MEMS are then integrated using processes such as thin-film deposition and doping.

Applications

MEMS have a wide range of applications in various fields. Some of the most common applications of MEMS include sensors, actuators, and microstructures.

Sensors

MEMS sensors are used in a variety of applications, including pressure sensors, accelerometers, gyroscopes, and microphones. These sensors work by converting a measured mechanical signal into an electrical signal.

Actuators

MEMS actuators are devices that convert an electrical signal into a mechanical action. These devices are used in applications such as micro relays, micro valves, and optical switches.

Microstructures

MEMS microstructures are used in applications such as micro mirrors, micro resonators, and micro fluidic devices. These structures are typically made using processes such as surface micromachining and bulk micromachining.

Future Trends

The field of MEMS is constantly evolving, with new applications and technologies being developed on a regular basis. Some of the future trends in MEMS include the development of nano-electromechanical systems (NEMS), the integration of MEMS with nanotechnology, and the use of MEMS in biomedical applications.