Direct Laser Writing

Introduction

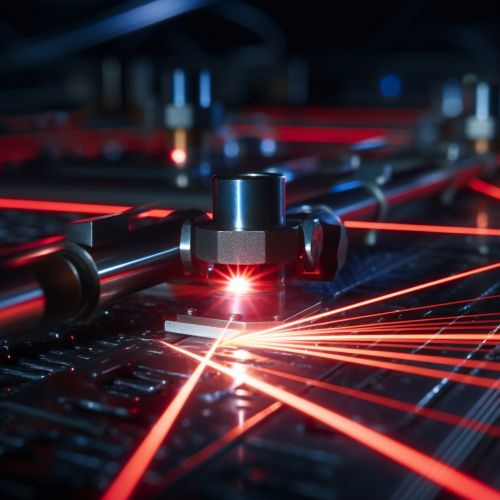

Direct Laser Writing (DLW) is a technique used in microfabrication and nanotechnology to create three-dimensional structures with high precision. This process involves the use of focused laser beams to induce chemical or physical changes in a photosensitive material, which can be selectively removed or solidified to create the desired structure.

Principles of Direct Laser Writing

DLW operates on the principle of two-photon absorption, a nonlinear optical process where two photons are simultaneously absorbed by a molecule, exciting it to a higher energy state. This process is highly localized, occurring only at the focal point of the laser, allowing for precise control over the writing process.

The photosensitive material, often a photopolymer or photoresist, undergoes a chemical or physical change when exposed to the laser. In the case of photopolymers, the laser exposure causes polymerization, solidifying the material. For photoresists, the exposure either enhances or reduces the material's solubility in a developer solution, allowing the exposed or unexposed regions to be selectively removed.

Advantages and Limitations of Direct Laser Writing

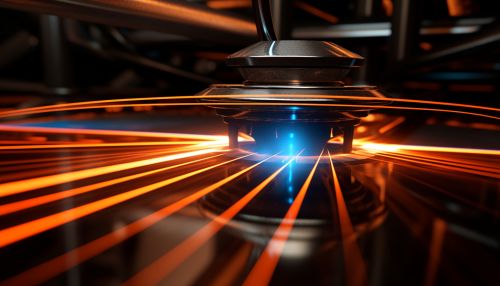

DLW offers several advantages over other microfabrication and nanofabrication techniques. It allows for the creation of complex three-dimensional structures with high resolution, typically in the range of 100 nm to a few micrometers. It also provides a high degree of flexibility, as the structures can be easily modified by changing the laser's path.

However, DLW also has certain limitations. The process is inherently serial, making it slower than parallel fabrication techniques like photolithography. The resolution of the structures is also limited by the diffraction limit of the laser, although techniques like stimulated emission depletion (STED) can be used to overcome this limitation.

Applications of Direct Laser Writing

DLW has found applications in various fields due to its ability to create complex three-dimensional structures. In microelectronics, it is used to create micro- and nano-scale components. In biotechnology, it is used to fabricate scaffolds for tissue engineering and to create microenvironments for studying cell behavior. In photonics, it is used to create photonic crystals and waveguides.

Future Directions

Research in DLW is currently focused on improving the speed and resolution of the process. Techniques like parallelized DLW and STED-DLW are being developed to address these issues. Additionally, new photosensitive materials are being explored to expand the capabilities of DLW.