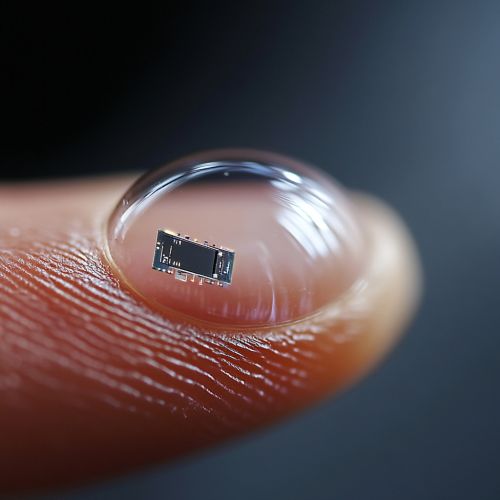

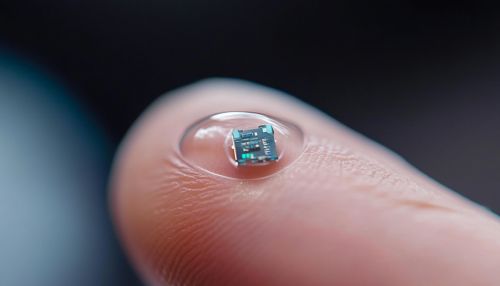

Smart Contact Lens Components

Introduction

Smart contact lenses represent a cutting-edge convergence of optical technology and wearable electronics. These advanced devices are designed to provide augmented vision capabilities, health monitoring, and connectivity features. The components of smart contact lenses are intricately designed to maintain the lens's primary function of vision correction while integrating additional functionalities. This article delves into the various components that constitute smart contact lenses, exploring their roles, materials, and technological innovations.

Core Components

Lens Substrate

The lens substrate is the foundational component of a smart contact lens, typically made from hydrogel or silicone hydrogel materials. These materials are selected for their biocompatibility, oxygen permeability, and comfort. The substrate serves as the base upon which other components are integrated, ensuring that the lens remains flexible and comfortable for the wearer.

Power Source

A critical challenge in smart contact lens design is the integration of a reliable power source. Current solutions include micro-batteries, energy harvesting systems, and wireless power transfer. Micro-batteries are typically thin-film lithium-ion cells, providing sufficient energy for short-term use. Energy harvesting systems may utilize piezoelectric materials or thermoelectric materials to convert mechanical or thermal energy into electrical energy. Wireless power transfer employs inductive coupling or radio frequency methods to deliver power to the lens without physical connections.

Sensors

Smart contact lenses incorporate a variety of sensors to monitor physiological parameters and environmental conditions. Common sensors include:

- **Glucose Sensors**: Utilized for continuous glucose monitoring in diabetic patients. These sensors typically employ enzymatic glucose oxidase reactions to detect glucose levels in tear fluid.

- **Intraocular Pressure Sensors**: Used to monitor intraocular pressure for glaucoma management. These sensors often use micro-electromechanical systems (MEMS) technology to provide accurate readings.

- **Environmental Sensors**: Measure external factors such as light intensity, temperature, and humidity. These sensors can enhance augmented reality applications by adapting display settings based on environmental conditions.

Display Technology

The display technology in smart contact lenses enables augmented reality (AR) applications by projecting images or information directly onto the user's field of vision. Micro-LEDs and organic light-emitting diodes (OLEDs) are commonly used due to their low power consumption and high brightness. The display system is often integrated with waveguide optics to direct light efficiently into the eye.

Communication Module

Communication modules in smart contact lenses facilitate data transmission between the lens and external devices. This is typically achieved through Bluetooth or near-field communication (NFC) protocols. These modules enable real-time data exchange, allowing users to receive notifications, health alerts, or interact with other smart devices seamlessly.

Advanced Materials and Fabrication Techniques

Conductive Polymers

Conductive polymers are essential for creating flexible electronic circuits within smart contact lenses. These materials, such as polyaniline and poly(3,4-ethylenedioxythiophene) (PEDOT), provide the necessary electrical conductivity while maintaining flexibility and transparency.

Nanotechnology

Nanotechnology plays a pivotal role in the miniaturization and integration of components within smart contact lenses. Nanostructured materials, such as carbon nanotubes and graphene, are utilized to enhance the electrical and mechanical properties of the lens components. These materials enable the development of ultra-thin sensors and circuits that do not compromise the lens's optical clarity.

Microfabrication Techniques

Microfabrication techniques, including photolithography and etching, are employed to create the intricate patterns and structures required for smart contact lens components. These techniques allow for the precise placement of sensors, circuits, and other elements on the lens substrate, ensuring optimal performance and functionality.

Challenges and Considerations

Biocompatibility

Ensuring biocompatibility is paramount in the development of smart contact lenses. All materials and components must be non-toxic and non-irritating to the eye. Extensive testing is required to verify that the lenses do not cause adverse reactions or interfere with normal ocular functions.

Power Management

Efficient power management is crucial for the practical use of smart contact lenses. Developers must balance the power consumption of various components with the available energy supply. This involves optimizing the energy efficiency of sensors, displays, and communication modules, as well as exploring innovative power solutions.

Data Privacy and Security

As smart contact lenses collect and transmit personal health data, ensuring data privacy and security is a significant concern. Robust encryption protocols and secure data storage methods are essential to protect user information from unauthorized access or breaches.

Future Prospects

The future of smart contact lenses holds exciting possibilities, with ongoing research and development aimed at enhancing their capabilities. Potential advancements include:

- **Enhanced Augmented Reality**: Improved display technologies and integration with artificial intelligence could enable more sophisticated AR applications, such as real-time language translation or advanced navigation aids.

- **Expanded Health Monitoring**: The incorporation of additional sensors could allow for the monitoring of a broader range of health parameters, such as blood oxygen levels or biomarkers for specific diseases.

- **Improved Power Solutions**: Continued innovation in energy harvesting and wireless power transfer could extend the operational lifespan of smart contact lenses, making them more practical for everyday use.