Pulsed Laser Deposition

Introduction

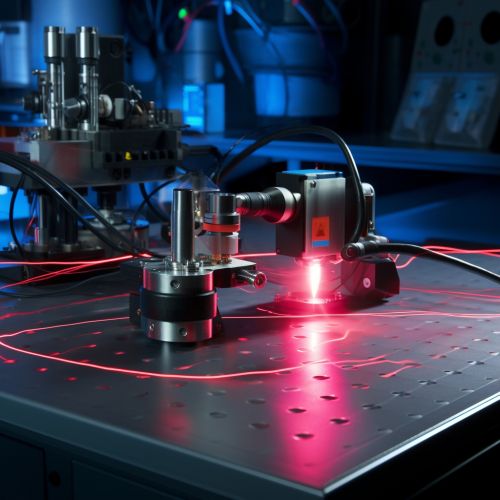

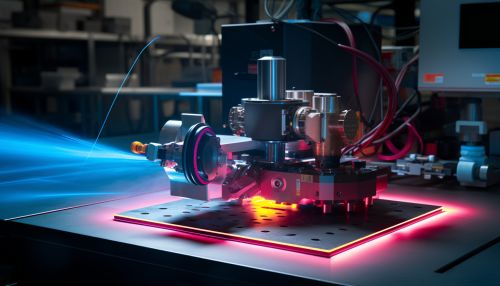

Pulsed laser deposition (PLD) is a physical vapor deposition (PVD) technique where a high-power pulsed laser beam is focused inside a vacuum chamber to strike a target of the material that is to be deposited. This material is vaporized from the target (in a plasma plume) which deposits it as a thin film on a substrate (such as a silicon wafer). This process can occur in ultra high vacuum or in the presence of a background gas, such as oxygen. Oxygen is commonly used when depositing oxides to fully oxygenate the deposited films.

History

The technique of pulsed laser deposition started to gain prominence in the late 1980s with the discovery of high-temperature superconductors. Prior to this, laser ablation was used primarily to study the composition of solid samples in a technique known as laser-induced breakdown spectroscopy (LIBS). The ability of PLD to create high-quality, high-temperature superconducting films led to a rapid increase in its use, and it is now employed in the deposition of many different types of material.

Process

The process begins with a short (typically nanosecond) pulse from a high-power laser (typically an excimer or Nd:YAG laser) being focused onto a target of the material to be deposited. This material is vaporized from the target in the form of a plasma plume, which then deposits onto a substrate to form a thin film. The process can occur in ultra high vacuum or in the presence of a background gas, such as oxygen when depositing oxides.

Advantages and Disadvantages

One of the key advantages of pulsed laser deposition is the high quality of the films that it can produce. Because the process does not involve any chemical reactions (unlike many other thin film deposition techniques), it is possible to deposit a wide range of materials, including metals, semiconductors, and high-temperature superconductors. The process is also relatively simple and can be carried out in a small laboratory setup.

However, there are also some disadvantages to the technique. The process is not easily scalable for industrial applications, as the deposition rate is relatively low and the area over which films can be deposited is small. The films can also be quite rough, particularly if the background gas pressure is high.

Applications

Pulsed laser deposition has been used to deposit a wide range of materials for various applications. These include high-temperature superconductors, ferroelectric materials, multilayer structures for magnetic applications, and thin film batteries. The technique is also used in the research and development of new materials and structures.