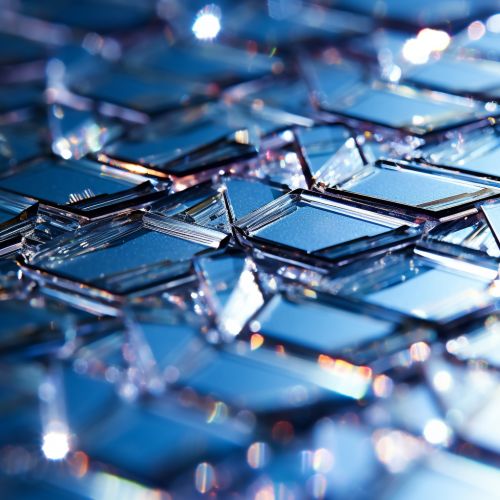

Polycrystalline solar cells

Introduction

Polycrystalline solar cells, also known as multi-crystalline, or many-crystal silicon cells, are a type of photovoltaic cell used in the production of solar panels. These cells are composed of multiple smaller silicon crystals, which are formed by melting and recrystallizing silicon. This process results in a cell with a mosaic appearance, hence the term 'polycrystalline'.

Production Process

The production of polycrystalline solar cells begins with the extraction of silicon, the second most abundant element on Earth. This silicon is then purified and melted in a crucible at temperatures exceeding 1400 degrees Celsius. Once the silicon has melted, a seed crystal is introduced into the crucible, and the silicon is allowed to cool and recrystallize around this seed. The resulting block of silicon, known as an ingot, is then sliced into thin wafers, which are the basis for the solar cells.

Structure and Function

Each polycrystalline solar cell is made up of multiple smaller silicon crystals. These crystals are less efficient at converting sunlight into electricity than single-crystal cells, due to the presence of grain boundaries, which disrupt the flow of electrons. However, they are cheaper to produce and offer a good balance between cost and efficiency.

When sunlight hits the surface of a polycrystalline solar cell, photons are absorbed by the silicon crystals, causing electrons to be knocked loose. These free electrons are then captured and directed into an electrical circuit, generating electricity.

Efficiency and Performance

The efficiency of polycrystalline solar cells is typically around 15-17%, although this can vary depending on the quality of the silicon used and the manufacturing process. While this is lower than the efficiency of monocrystalline solar cells, which can reach up to 20%, polycrystalline cells are cheaper to produce and can therefore offer a better return on investment in certain situations.

The performance of polycrystalline solar cells can be affected by a number of factors, including temperature, light intensity, and the angle of the sun. Like all solar cells, they perform best under direct sunlight and at cooler temperatures.

Advantages and Disadvantages

One of the main advantages of polycrystalline solar cells is their cost-effectiveness. They are cheaper to produce than monocrystalline cells, due to the simpler manufacturing process, and this cost saving is often passed on to the consumer.

However, polycrystalline solar cells also have a number of disadvantages. They are less efficient than monocrystalline cells, and their performance can be affected by high temperatures and low light conditions. In addition, the presence of multiple crystals in each cell can lead to a lower aesthetic appeal for some consumers.

Future Developments

Research is currently being conducted into ways to improve the efficiency and performance of polycrystalline solar cells. This includes the development of new manufacturing techniques, as well as the use of innovative materials and designs.