Plasma Enhanced Chemical Vapor Deposition

Introduction

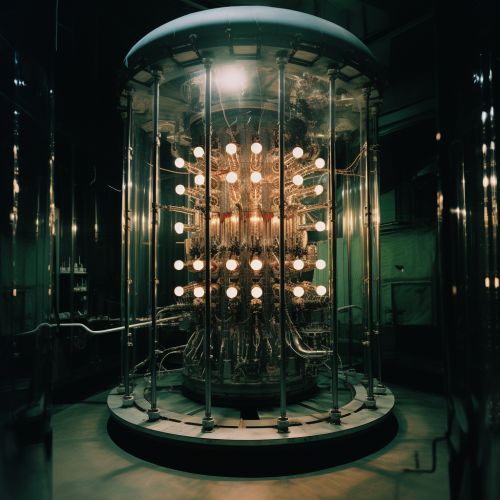

Plasma Enhanced Chemical Vapor Deposition (PECVD) is a process used in thin film fabrication. This technique uses plasma to enhance the reaction rate of the chemical vapor deposition process, allowing for lower temperatures to be used compared to other deposition techniques.

Process

The PECVD process begins with the introduction of a gaseous precursor into a chamber containing the substrate. The gas is then ionized into a plasma state using an external energy source, such as a radio frequency (RF) power supply. The plasma contains a high concentration of reactive species, which react with the precursor to form a thin film on the substrate.

Advantages

PECVD offers several advantages over other deposition techniques. The use of plasma allows for lower deposition temperatures, which can be beneficial for temperature-sensitive substrates. The process also provides good step coverage, making it ideal for depositing films on complex geometries. Furthermore, PECVD allows for the deposition of a wide range of materials, including silicon dioxide, silicon nitride, and amorphous silicon.

Applications

PECVD is widely used in the fabrication of semiconductor devices, including integrated circuits and solar cells. In the field of optoelectronics, PECVD is used to deposit anti-reflection coatings on LEDs and laser diodes. The process is also used in the production of protective coatings for various industrial applications.