Optical coating

Introduction

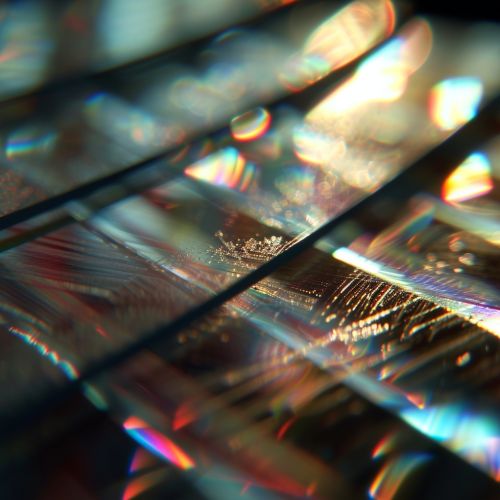

Optical coating refers to the application of one or more thin layers of material onto an optical component such as a lens or mirror, which reduces reflection and enhances transmission, filter, or polarization properties. This process is fundamental to many areas of photonics, including lasers, fiber optics, and astronomy.

History

The concept of optical coating dates back to the late 17th century when Isaac Newton discovered that certain substances could alter the color of light. However, it was not until the 19th century that the first practical optical coatings were developed. These early coatings were primarily used in the production of microscopes and telescopes.

Types of Optical Coatings

There are several types of optical coatings, each with its own unique properties and applications. These include anti-reflection coatings, high-reflection coatings, beam splitter coatings, and filter coatings.

Anti-Reflection Coatings

Anti-reflection (AR) coatings are designed to reduce the amount of light that is reflected off the surface of an optical component. This is achieved by applying a thin layer of material with a specific refractive index and thickness that causes destructive interference for reflected light.

High-Reflection Coatings

High-reflection (HR) coatings, also known as mirror coatings, are used to reflect as much light as possible. These coatings are typically used in laser cavities and astronomical telescopes.

Beam Splitter Coatings

Beam splitter coatings are used to divide a beam of light into two or more separate beams. This is often used in interferometry, an important technique in the field of physics.

Filter Coatings

Filter coatings are used to transmit certain wavelengths of light while reflecting others. These coatings are commonly used in applications such as color imaging and fluorescence microscopy.

Coating Techniques

There are several techniques used to apply optical coatings, including physical vapor deposition (PVD), chemical vapor deposition (CVD), and atomic layer deposition (ALD).

Physical Vapor Deposition

Physical vapor deposition (PVD) is a process in which a material is vaporized in a vacuum and then deposited onto the surface of an optical component. This method is commonly used to apply anti-reflection and high-reflection coatings.

Chemical Vapor Deposition

Chemical vapor deposition (CVD) involves the reaction of gaseous chemicals on the surface of an optical component to form a thin film. This technique is often used to apply filter coatings.

Atomic Layer Deposition

Atomic layer deposition (ALD) is a process in which thin films are deposited one atomic layer at a time. This method allows for precise control over the thickness and composition of the coating, making it ideal for complex optical coatings.

Applications

Optical coatings are used in a wide range of applications, from consumer electronics to scientific research. Some of the most common applications include laser systems, fiber optic networks, astronomical telescopes, microscopes, and optical sensors.

Future Developments

The field of optical coatings is constantly evolving, with new materials and techniques being developed to improve the performance and durability of optical components. Future developments are likely to focus on the creation of coatings with even greater precision and versatility, as well as the development of more environmentally friendly coating processes.