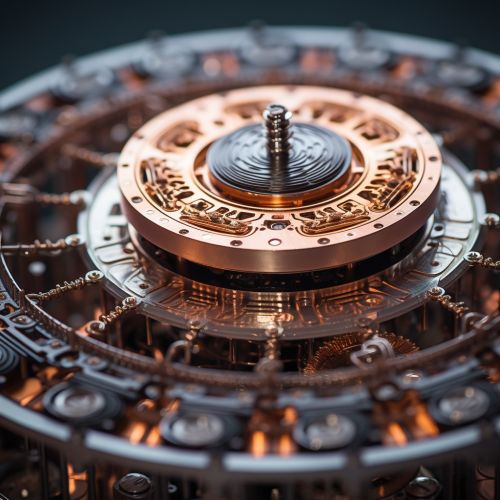

Micro-mechanical resonator

Introduction

A micro-mechanical resonator is a device that exploits the mechanical resonance of a vibrating structure to perform a specific function. These devices are typically fabricated using microfabrication or nanofabrication techniques, similar to those used in the production of microelectromechanical systems (MEMS).

Design and Operation

The design of a micro-mechanical resonator involves the creation of a structure that can vibrate at a specific frequency. This is typically achieved by designing the structure to have a specific shape and size, and by selecting a material that has the appropriate mechanical properties. The operation of the resonator involves driving the structure to vibrate at its resonant frequency, and then using the resulting vibrations to perform a specific function.

The resonant frequency of a micro-mechanical resonator is determined by its physical dimensions and the mechanical properties of the material from which it is made. For example, a resonator made from a stiffer material, or one that is smaller in size, will have a higher resonant frequency.

Types of Micro-Mechanical Resonators

There are several different types of micro-mechanical resonators, each of which is designed to exploit a different type of mechanical resonance. These include:

- Beam resonators: These are the simplest type of resonator, and consist of a beam that is clamped at both ends. The beam can vibrate in a number of different modes, each of which has a different resonant frequency.

- Membrane resonators: These consist of a thin membrane that is clamped around its edges. The membrane can vibrate in a number of different modes, similar to the surface of a drum.

- Disk resonators: These consist of a thin disk that is clamped around its edge. The disk can vibrate in a number of different radial and torsional modes.

- Ring resonators: These consist of a thin ring that is free to vibrate. The ring can vibrate in a number of different radial and torsional modes.

- Cantilever resonators: These consist of a beam that is clamped at one end and free at the other. The cantilever can vibrate in a number of different modes, each of which has a different resonant frequency.

Applications

Micro-mechanical resonators have a wide range of applications, due to their ability to operate at high frequencies and their compatibility with microfabrication techniques. Some of the most common applications include:

- Sensors: Micro-mechanical resonators can be used to create highly sensitive sensors for measuring a variety of physical quantities, such as force, pressure, temperature, and chemical composition.

- Filters: In radio frequency (RF) applications, micro-mechanical resonators can be used to create filters that allow certain frequencies to pass while blocking others.

- Oscillators: Micro-mechanical resonators can be used to create oscillators that generate a stable frequency output. These can be used in a variety of applications, including timekeeping and frequency synthesis.

- Signal processing: Micro-mechanical resonators can be used in signal processing applications to perform functions such as modulation, demodulation, and mixing.