Digital Integrated Circuits

Introduction

Digital integrated circuits (ICs) are a cornerstone of modern electronics, forming the basis for a wide range of devices from simple calculators to complex computers and communication systems. These circuits are composed of numerous interconnected transistors, resistors, capacitors, and other electronic components, all fabricated onto a single piece of semiconductor material, typically silicon. Digital ICs operate using binary logic, where signals are represented by two distinct voltage levels corresponding to logical '0' and '1'.

History and Development

The development of digital integrated circuits can be traced back to the invention of the transistor in 1947 by John Bardeen, Walter Brattain, and William Shockley at Bell Labs. This breakthrough paved the way for the miniaturization of electronic components. The first practical IC was developed by Jack Kilby at Texas Instruments in 1958, followed by Robert Noyce at Fairchild Semiconductor, who improved the design by introducing the planar process, which became the foundation for modern IC fabrication.

The evolution of digital ICs has been driven by Moore's Law, an observation made by Gordon Moore in 1965, which predicted that the number of transistors on a chip would double approximately every two years. This trend has led to exponential increases in processing power and reductions in cost and size, enabling the proliferation of digital technology in virtually every aspect of modern life.

Types of Digital Integrated Circuits

Digital ICs can be broadly categorized into several types based on their functionality and complexity:

Logic Gates

Logic gates are the fundamental building blocks of digital circuits. They perform basic logical functions such as AND, OR, NOT, NAND, NOR, XOR, and XNOR. These gates are used to create more complex circuits like adders, multiplexers, and memory cells.

Microprocessors

Microprocessors are complex ICs that serve as the central processing unit (CPU) of a computer. They execute instructions from a program, performing arithmetic, logic, control, and input/output operations. Modern microprocessors contain millions to billions of transistors and are capable of executing billions of instructions per second.

Memory Chips

Memory chips store data and instructions for use by a computer or other digital devices. They come in various forms, including Random Access Memory (RAM), Read-Only Memory (ROM), and flash memory. RAM is volatile memory used for temporary data storage, while ROM is non-volatile and used for permanent storage of firmware.

Application-Specific Integrated Circuits (ASICs)

ASICs are custom-designed ICs tailored for specific applications. They are used in a wide range of products, from consumer electronics to industrial equipment. ASICs offer optimized performance and power efficiency for their intended tasks but require significant design and manufacturing effort.

Field-Programmable Gate Arrays (FPGAs)

FPGAs are reconfigurable ICs that can be programmed by the user to perform specific functions. They consist of an array of programmable logic blocks and interconnects that can be configured to implement custom digital circuits. FPGAs offer flexibility and rapid prototyping capabilities, making them popular in research and development.

Fabrication Process

The fabrication of digital ICs involves several key steps, including:

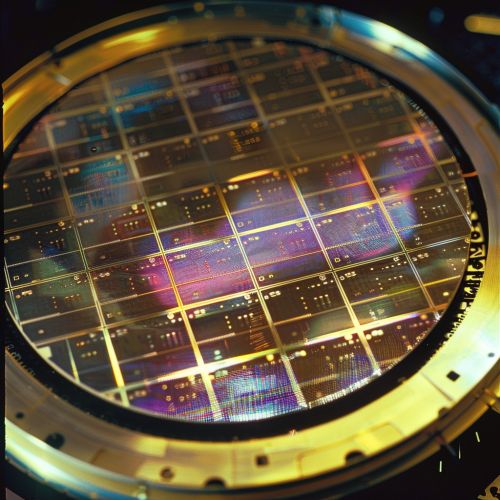

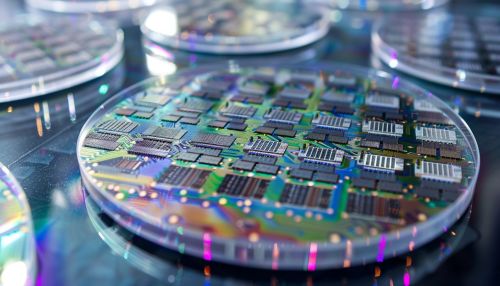

Wafer Production

The process begins with the production of a silicon wafer. High-purity silicon is melted and crystallized into a cylindrical ingot, which is then sliced into thin wafers. These wafers serve as the substrate for the ICs.

Photolithography

Photolithography is used to transfer the circuit design onto the wafer. A light-sensitive photoresist is applied to the wafer, and ultraviolet light is used to expose the desired pattern. The exposed areas are then etched away, creating the circuit features.

Doping

Doping involves introducing impurities into the silicon to modify its electrical properties. This is done using ion implantation or diffusion processes. Doping creates regions of n-type and p-type silicon, which are essential for forming transistors and other components.

Deposition and Etching

Various materials, such as metals and insulators, are deposited onto the wafer to form interconnects and other structures. Chemical and physical etching techniques are used to remove unwanted material and shape the features of the IC.

Packaging

Once the ICs are fabricated, they are tested and packaged to protect them from physical damage and environmental factors. Packaging also provides the necessary electrical connections to integrate the IC into a larger system.

Design and Simulation

The design of digital ICs involves several stages, including:

Specification

The design process begins with defining the specifications of the IC, including its functionality, performance, power consumption, and physical dimensions.

Schematic Design

A schematic diagram is created to represent the circuit at a high level. This diagram shows the connections between different components and their interactions.

Layout Design

The layout design involves translating the schematic into a physical representation of the IC. This includes placing the components on the wafer and routing the interconnections.

Simulation

Simulation tools are used to verify the functionality and performance of the design before fabrication. These tools model the behavior of the circuit and identify potential issues.

Verification

Verification ensures that the design meets the specifications and is free of errors. This includes functional verification, timing analysis, and power analysis.

Applications

Digital ICs are used in a wide range of applications, including:

Consumer Electronics

Digital ICs are integral to consumer electronics such as smartphones, tablets, laptops, and gaming consoles. They enable advanced features like high-resolution displays, fast processing, and connectivity.

Telecommunications

In telecommunications, digital ICs are used in devices such as routers, modems, and base stations. They enable high-speed data transmission, signal processing, and network management.

Automotive

The automotive industry relies on digital ICs for various functions, including engine control, infotainment systems, and advanced driver-assistance systems (ADAS). These ICs enhance vehicle performance, safety, and user experience.

Industrial Automation

Digital ICs are used in industrial automation for process control, robotics, and monitoring systems. They enable precise control, data acquisition, and real-time processing.

Medical Devices

In the medical field, digital ICs are used in diagnostic equipment, imaging systems, and wearable health monitors. They provide accurate measurements, data analysis, and connectivity for remote monitoring.

Future Trends

The future of digital ICs is shaped by several emerging trends:

Scaling and Miniaturization

Continued scaling and miniaturization of transistors, guided by Moore's Law, will enable even higher levels of integration and performance. Advanced lithography techniques, such as extreme ultraviolet (EUV) lithography, are being developed to achieve smaller feature sizes.

3D Integration

3D integration involves stacking multiple layers of ICs vertically to increase density and performance. This approach reduces interconnect lengths and improves signal speed and power efficiency.

Quantum Computing

Quantum computing represents a paradigm shift in computing technology. Quantum ICs leverage the principles of quantum mechanics to perform computations that are infeasible for classical digital ICs. Research in this area is ongoing, with the potential to revolutionize fields such as cryptography and optimization.

Neuromorphic Computing

Neuromorphic computing aims to mimic the structure and function of the human brain using specialized ICs. These ICs are designed to perform tasks such as pattern recognition and learning with high efficiency and low power consumption.

Internet of Things (IoT)

The proliferation of IoT devices is driving the demand for low-power, high-performance digital ICs. These ICs enable connectivity, data processing, and control in a wide range of applications, from smart homes to industrial automation.

Conclusion

Digital integrated circuits are a fundamental technology that underpins modern electronics. Their development has been driven by advances in semiconductor fabrication, design methodologies, and emerging applications. As technology continues to evolve, digital ICs will play a crucial role in shaping the future of computing, communication, and automation.