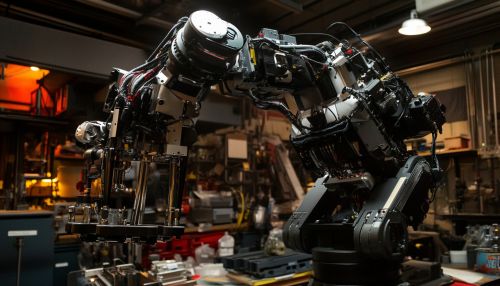

ATC Robotic Arm

Introduction

The ATC Robotic Arm represents a significant advancement in the field of automation and robotics. Designed for precision, versatility, and efficiency, these robotic arms are utilized across various industries, including manufacturing, healthcare, and research. The term "ATC" typically refers to "Automatic Tool Changer," a feature that enhances the robotic arm's capability to perform multiple tasks without manual intervention. This article delves into the intricate design, functionality, and applications of ATC Robotic Arms, providing a comprehensive understanding of their role in modern technology.

Design and Components

ATC Robotic Arms are engineered with a combination of mechanical, electrical, and software components that work in harmony to execute complex tasks. The primary components include:

Mechanical Structure

The mechanical structure of an ATC Robotic Arm consists of several joints and links, which mimic the movement of a human arm. These joints are typically powered by servo motors, allowing precise control over the arm's motion. The design often includes:

- **Base**: The foundation that supports the arm and houses the motors and controllers.

- **Joints**: Typically rotary or linear, these provide the arm with degrees of freedom.

- **End Effector**: The tool or device attached to the arm's end, which interacts with the environment.

Control Systems

The control system of an ATC Robotic Arm is crucial for its operation. It consists of hardware and software components that manage the arm's movements and tasks. Key elements include:

- **Microcontrollers**: These serve as the brain of the robotic arm, processing inputs and controlling outputs.

- **Sensors**: Devices such as proximity sensors, encoders, and cameras provide feedback to ensure accuracy and safety.

- **Software**: Advanced algorithms and programming languages like Python or C++ are used to program the arm's tasks and movements.

Automatic Tool Changer (ATC)

The ATC is a pivotal feature that allows the robotic arm to switch between different tools automatically. This capability is essential for tasks that require multiple operations, such as drilling, welding, and assembly. The ATC system typically includes:

- **Tool Magazine**: A storage unit that holds various tools.

- **Tool Holder**: A mechanism that securely attaches tools to the arm.

- **Control Interface**: Software that manages tool selection and changes.

Functionality and Operation

The operation of an ATC Robotic Arm involves a series of coordinated actions, driven by sophisticated control systems. The functionality can be categorized into several key areas:

Motion Control

Motion control is fundamental to the robotic arm's operation. It involves the precise movement of joints and links to achieve desired positions and orientations. Techniques such as Inverse Kinematics are employed to calculate joint angles for specific tasks.

Task Automation

ATC Robotic Arms are designed to automate repetitive and complex tasks. This capability is achieved through programming and integration with other systems, such as CAD and CAM software. Automation enhances efficiency and reduces human error.

Safety and Compliance

Ensuring safety is paramount in the operation of robotic arms. ATC Robotic Arms are equipped with safety features such as emergency stop buttons, collision detection sensors, and compliance with industry standards like ISO 10218 for industrial robots.

Applications

ATC Robotic Arms are employed in a wide range of applications, each benefiting from their precision and adaptability:

Manufacturing

In the manufacturing sector, ATC Robotic Arms are used for tasks such as assembly, material handling, and quality inspection. Their ability to switch tools automatically makes them ideal for production lines that require versatility.

Healthcare

In healthcare, robotic arms assist in surgeries, rehabilitation, and laboratory automation. Their precision and control are invaluable in delicate procedures, such as robotic surgery.

Research and Development

Research institutions utilize ATC Robotic Arms for experiments that require high precision and repeatability. They are also used in the development of new robotic technologies and applications.

Challenges and Future Directions

Despite their advantages, ATC Robotic Arms face challenges such as high costs, complexity in programming, and integration with existing systems. Future developments aim to address these issues by enhancing user interfaces, reducing costs, and improving interoperability with other technologies.