Thermal Grease

Introduction

Thermal grease, also known as thermal paste, thermal compound, or thermal interface material (TIM), is a thermally conductive compound used to enhance the thermal conductivity between two surfaces. It is commonly used in electronics and computer hardware to improve the heat transfer between a heat-generating component, such as a central processing unit (CPU) or graphics processing unit (GPU), and a heat sink or cooling solution. The primary purpose of thermal grease is to fill the microscopic air gaps and irregularities on the surfaces of the components, thereby reducing thermal resistance and improving heat dissipation.

Composition and Properties

Thermal grease is typically composed of a polymer matrix filled with thermally conductive materials. The matrix can be made from silicone, epoxy, or other synthetic compounds, while the fillers are usually metal oxides, such as aluminum oxide, zinc oxide, or boron nitride. Some high-performance thermal greases may also contain silver or diamond particles due to their superior thermal conductivity.

The key properties of thermal grease include:

- **Thermal Conductivity:** This measures the ability of the grease to conduct heat. It is usually expressed in watts per meter-kelvin (W/m·K). Higher thermal conductivity indicates better performance.

- **Viscosity:** This refers to the thickness or consistency of the grease. A balance between high and low viscosity is essential for easy application and effective gap filling.

- **Electrical Conductivity:** Ideally, thermal grease should be electrically insulating to prevent short circuits. However, some high-performance greases with metal fillers may be slightly conductive.

- **Operating Temperature Range:** Thermal grease should remain stable and effective over a wide range of temperatures, typically from -50°C to 150°C or higher.

Application and Usage

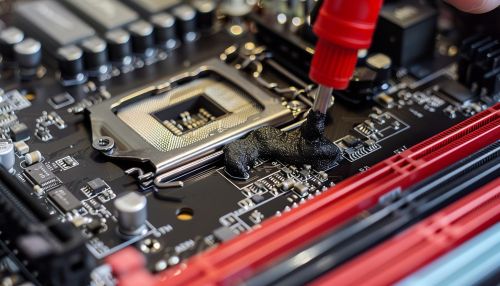

The application of thermal grease is a critical step in assembling electronic devices and computer systems. Proper application ensures optimal thermal performance and longevity of the components. The general steps for applying thermal grease are as follows:

1. **Surface Preparation:** Clean the surfaces of the CPU and heat sink thoroughly to remove any old thermal grease, dust, or debris. Use isopropyl alcohol and a lint-free cloth for best results. 2. **Application:** Apply a small amount of thermal grease to the center of the CPU. The amount should be roughly the size of a pea or a grain of rice, depending on the CPU size. 3. **Spreading:** Some methods involve spreading the grease evenly across the surface using a plastic card or a dedicated applicator. Others rely on the pressure of the heat sink to spread the grease naturally. 4. **Mounting the Heat Sink:** Carefully place the heat sink onto the CPU, ensuring even pressure to avoid air bubbles. Secure the heat sink according to the manufacturer's instructions.

Types of Thermal Grease

Thermal greases can be categorized based on their composition and performance characteristics:

- **Silicone-Based Grease:** Commonly used due to its affordability and ease of application. Suitable for general-purpose applications.

- **Metal-Based Grease:** Contains metal particles like silver or aluminum, offering higher thermal conductivity. Ideal for high-performance computing and overclocking.

- **Ceramic-Based Grease:** Uses ceramic particles such as aluminum oxide or zinc oxide. Provides a good balance between performance and electrical insulation.

- **Carbon-Based Grease:** Contains carbon compounds like graphite or diamond. Known for excellent thermal conductivity and stability.

Performance and Testing

The performance of thermal grease is evaluated through various testing methods, including:

- **Thermal Conductivity Measurement:** Using techniques like the laser flash method or guarded hot plate method to determine the grease's thermal conductivity.

- **Thermal Resistance Testing:** Measuring the temperature difference across the thermal interface material under a known heat load to calculate thermal resistance.

- **Long-Term Stability Testing:** Assessing the grease's performance over extended periods and under varying environmental conditions to ensure reliability.

Factors Affecting Performance

Several factors can influence the performance of thermal grease, including:

- **Application Technique:** Uneven application or excessive amounts can create air pockets, reducing thermal conductivity.

- **Aging and Pump-Out:** Over time, thermal grease can dry out or migrate from the interface, leading to decreased performance.

- **Surface Roughness:** The roughness of the mating surfaces affects the amount of grease required and its ability to fill gaps effectively.

- **Operating Conditions:** Extreme temperatures, humidity, and mechanical stress can impact the grease's stability and effectiveness.

Alternatives to Thermal Grease

While thermal grease is widely used, there are alternative thermal interface materials available, such as:

- **Thermal Pads:** Pre-formed pads made from thermally conductive materials. Easier to apply but may not offer the same performance as thermal grease.

- **Liquid Metal:** Composed of gallium or indium alloys, offering superior thermal conductivity. However, it is electrically conductive and can be challenging to apply.

- **Phase-Change Materials:** Solid at room temperature but become liquid at operating temperatures, filling gaps more effectively. Used in high-performance applications.