Sodium–sulfur battery

Introduction

Sodium–sulfur batteries are a type of molten salt battery constructed from liquid sodium (Na) and sulfur (S). This type of battery has a high energy density, high efficiency of charge/discharge and long cycle life, and is fabricated from inexpensive materials. However, because of the operating temperatures of 300 to 350 °C and the highly corrosive nature of the sodium polysulfides, such cells are primarily used for grid energy storage.

History

The development of the sodium–sulfur battery can be traced back to the 1960s at the Ford Motor Company. However, it was not until the 1980s that the technology was further developed by NGK Insulators, a Japanese company that is now the world's biggest supplier of large-size sodium–sulfur batteries.

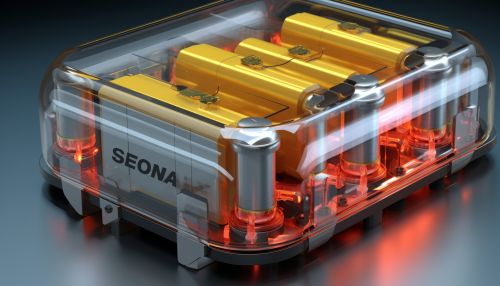

Structure and Composition

The sodium–sulfur battery is composed of two electrodes separated by a solid ceramic, sodium aluminum oxide electrolyte. The positive electrode or anode is molten sulfur, and the negative electrode or cathode is molten sodium. The battery operates at a temperature of 300 to 350 °C. The high operating temperature is maintained by self-heating during battery operation.

Working Principle

The sodium–sulfur battery operates by the chemical reaction of sodium and sulfur, which generates an electromotive force. During the discharge phase, the sodium atoms are oxidized at the anode, losing electrons to form sodium ions. These ions then migrate through the solid electrolyte to the cathode, where they react with the sulfur to form sodium polysulfides. During the charge phase, the process is reversed.

Applications

Sodium–sulfur batteries are primarily used for grid energy storage due to their high energy density, long cycle life, and high efficiency. They are also used in some electric vehicles and for storing wind and solar energy.

Advantages

The main advantages of sodium–sulfur batteries are their high energy density, long cycle life, and high efficiency. They are also made from inexpensive and abundant materials, which makes them cost-effective for large-scale energy storage.

Disadvantages

The main disadvantage of sodium–sulfur batteries is their high operating temperature, which can lead to safety issues. They also produce highly corrosive sodium polysulfides during operation.

Future Developments

Research is ongoing to improve the safety and performance of sodium–sulfur batteries. This includes the development of new materials for the electrolyte and electrodes, and the design of new battery architectures.