Shape memory alloys (SMAs)

Introduction

Shape memory alloys (SMAs) are a unique class of metal alloys that have the ability to return to their original shape after being deformed when subjected to a certain temperature or magnetic field. This property, known as the shape memory effect, is a result of a phase transformation that occurs in the alloy.

History

The first known shape memory alloy, nickel titanium (also known as Nitinol), was discovered in the 1960s by the U.S. Naval Ordnance Lab. Since then, a variety of other SMAs have been developed, including copper-aluminum-nickel, copper-zinc-aluminum, and iron-manganese-silicon alloys.

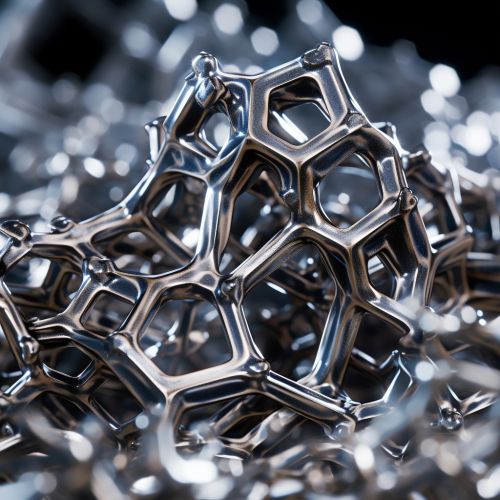

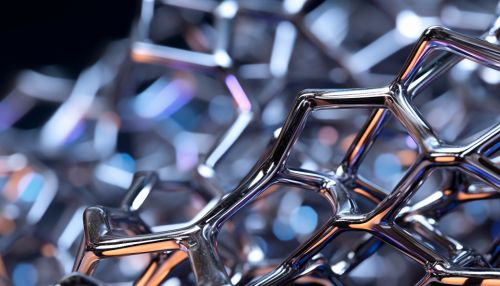

Structure and Properties

SMAs have a unique crystal structure that allows them to undergo a phase transformation. This transformation is what gives the alloys their shape memory effect. At high temperatures, SMAs have a crystal structure known as austenite, which is a cubic structure. When the alloy is cooled, it transforms into a different structure known as martensite, which is a more distorted, less symmetric structure. This transformation is reversible, so when the alloy is heated again, it returns to the austenite structure and its original shape.

Shape Memory Effect

The shape memory effect is the ability of an SMA to return to its original shape after being deformed. This is achieved through a phase transformation. When an SMA is deformed in its martensite state, the deformation is accommodated by the movement of twin boundaries within the structure. When the alloy is heated and transforms back to austenite, these twin boundaries move back to their original positions, and the alloy returns to its original shape.

Applications

SMAs have a wide range of applications due to their unique properties. They are used in various industries, including aerospace, automotive, medical, and consumer products. In the aerospace industry, SMAs are used in actuators for aircraft and spacecraft. In the automotive industry, they are used in thermostats and in safety devices such as airbag sensors. In the medical field, SMAs are used in devices such as stents and orthodontic wires. In consumer products, they are used in items such as eyeglass frames and bra underwires.

Future Developments

Research is currently being conducted to develop new SMAs with improved properties and to find new applications for these materials. This includes the development of high-temperature SMAs for use in aerospace and automotive applications, and the development of magnetic SMAs for use in actuators and sensors.

See Also