Polyhydroxyalkanoates

Overview

Polyhydroxyalkanoates (PHAs) are a class of polymeric materials that are produced by a variety of microorganisms as a means of storing energy. These polymers are unique in that they are both biodegradable and biocompatible, making them ideal for use in a variety of applications, including packaging, agriculture, and medicine.

Production

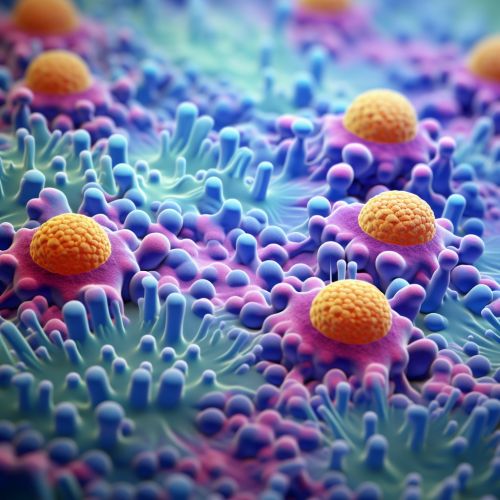

The production of PHAs occurs naturally in a variety of microorganisms, including bacteria and archaea. These organisms synthesize PHAs in response to environmental stress, such as nutrient limitation, and store them as energy reserves in the form of intracellular granules. The synthesis of PHAs involves the conversion of carbon sources, such as glucose or fatty acids, into hydroxy acids, which are then polymerized to form PHAs.

Types

There are several different types of PHAs, each with unique properties and potential applications. The most common types of PHAs include Poly(3-hydroxybutyrate) (P3HB), Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (P(HB-co-HV)), and Poly(3-hydroxyhexanoate) (P3HHx).

Properties

PHAs have a number of properties that make them attractive for use in a variety of applications. These include their biodegradability, biocompatibility, and thermoplasticity. In addition, PHAs have good barrier properties, which make them suitable for use in packaging applications. They also have good mechanical properties, including tensile strength and flexibility, which can be tailored by altering the composition of the PHA.

Applications

Due to their unique properties, PHAs have potential applications in a variety of fields. These include:

- Packaging: PHAs can be used to produce biodegradable packaging materials, which can help to reduce the environmental impact of plastic waste.

- Agriculture: PHAs can be used to produce controlled-release fertilizers and pesticides, as well as biodegradable mulch films.

- Medicine: PHAs can be used to produce biocompatible and biodegradable medical devices, such as sutures, bone plates, and drug delivery systems.

Environmental Impact

One of the key advantages of PHAs is their environmental friendliness. Unlike conventional plastics, which can take hundreds of years to degrade, PHAs are fully biodegradable and can be broken down by a variety of microorganisms in the environment. This makes them a promising alternative to traditional plastics in terms of reducing plastic pollution.

Challenges and Future Prospects

Despite their many advantages, the widespread adoption of PHAs has been hindered by several challenges. These include the high cost of production, the limited availability of suitable carbon sources, and the need for further research and development to improve the properties and performance of PHAs. However, with ongoing research and technological advancements, the future prospects for PHAs look promising.