Pneumatic Caisson

Introduction

A pneumatic caisson is a watertight structure made from wood, steel, or reinforced concrete, used in the construction of bridges, dams, and other large structures that are built over water or on soft ground. The caisson is filled with compressed air to keep water and mud out at depth.

History

The concept of the pneumatic caisson was first introduced in the 19th century by French engineer François Triger, who used it in the construction of the Loire River bridge. This innovative method allowed workers to excavate in dry conditions below the water table, which was a significant advancement in civil engineering at the time.

Design and Construction

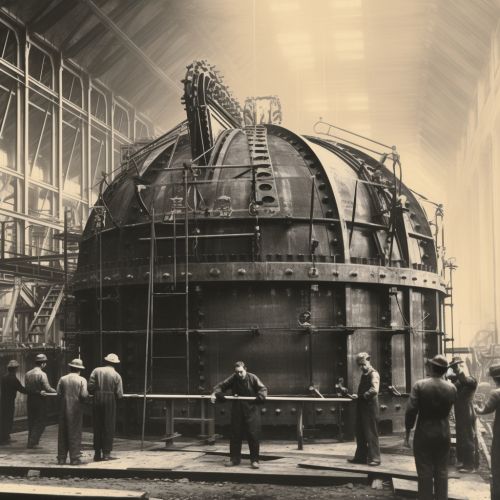

The design of a pneumatic caisson depends on the specific requirements of the project. However, all caissons share some common features. They are typically cylindrical in shape and have an airlock at the top for workers to enter and exit. The bottom of the caisson, known as the cutting edge, is sharp to allow it to be sunk into the ground.

The construction of a pneumatic caisson begins with the fabrication of the caisson itself. This is typically done on-site, using steel or reinforced concrete. Once the caisson is complete, it is positioned over the location where it will be sunk and filled with compressed air. The air pressure inside the caisson must be carefully controlled to prevent water and mud from entering.

Working Principle

The working principle of a pneumatic caisson is based on the physics of fluid dynamics. When the air pressure inside the caisson is greater than the hydrostatic pressure of the water outside, it prevents water and mud from entering the caisson. This creates a dry working environment, even at great depths below the water table.

Applications

Pneumatic caissons are used in a variety of construction projects. They are commonly used in the construction of bridge piers and abutments, as well as the foundations of large buildings and structures. They are also used in the construction of offshore oil platforms, where they provide a stable foundation on the ocean floor.

Safety Considerations

Working in a pneumatic caisson can be hazardous due to the high air pressure. Workers must undergo decompression procedures when exiting the caisson to prevent decompression sickness, also known as the bends. Other potential hazards include the risk of a blowout, where a sudden release of pressure can cause the caisson to rapidly rise or fall.

Advantages and Disadvantages

Pneumatic caissons offer several advantages over other types of caissons. They allow for construction in wet or unstable conditions, and they provide a dry working environment. However, they also have some disadvantages. The high air pressure can be hazardous to workers, and the construction process can be slow and expensive.