Piezoelectric actuator

Introduction

A Piezoelectric actuator is a device that uses the piezoelectric effect to control mechanical displacement. The piezoelectric effect is the ability of certain materials to generate an electric charge in response to applied mechanical stress. This property is used in a variety of practical applications such as the production and detection of sound, generation of high voltages, electronic frequency generation, microbalances, and ultrafine focusing of optical assemblies.

Principle of Operation

The piezoelectric actuator operates based on the direct piezoelectric effect, a property of certain materials that allows them to generate an electric charge in response to applied mechanical stress. Conversely, the inverse piezoelectric effect causes these materials to mechanically deform when an electric field is applied. In a piezoelectric actuator, an electric field is applied to a piezoelectric material, causing it to deform and generate motion.

Types of Piezoelectric Actuators

There are several types of piezoelectric actuators, each with its own unique characteristics and applications.

Stack Actuators

A stack actuator is a type of piezoelectric actuator that is composed of several thin layers of piezoelectric material stacked on top of each other. Each layer is separated by a thin electrode, and the entire assembly is polarized in the direction of the stack. When a voltage is applied, each layer expands or contracts, causing the entire stack to elongate or shorten.

Stripe Actuators

A stripe actuator, also known as a bimorph actuator, consists of two thin layers of piezoelectric material bonded together. When a voltage is applied, one layer expands while the other contracts, causing the actuator to bend. This type of actuator is commonly used in applications that require bending or twisting motion.

Tube Actuators

A tube actuator is a type of piezoelectric actuator that is shaped like a tube. The tube is made of piezoelectric material, and when a voltage is applied, the tube expands or contracts. This type of actuator is commonly used in applications that require linear motion.

Applications

Piezoelectric actuators have a wide range of applications due to their unique properties. They are used in many industries, including automotive, aerospace, medical, and consumer electronics.

Precision Positioning

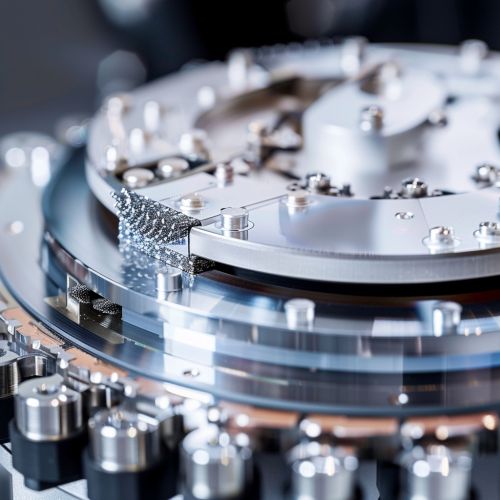

One of the most common applications of piezoelectric actuators is in precision positioning systems. These systems are used in a variety of fields, including microscopy, semiconductor manufacturing, and nanotechnology. The high resolution and fast response time of piezoelectric actuators make them ideal for these applications.

Vibration Control

Piezoelectric actuators are also used in vibration control systems. These systems are used to reduce or eliminate unwanted vibrations in a variety of applications, from automotive suspension systems to optical image stabilization in cameras.

Energy Harvesting

Another application of piezoelectric actuators is in energy harvesting systems. These systems convert mechanical energy, such as vibrations or impacts, into electrical energy. This can be used to power small electronic devices, such as sensors or wireless communication devices.

Advantages and Disadvantages

Like all technologies, piezoelectric actuators have both advantages and disadvantages.

Advantages

One of the main advantages of piezoelectric actuators is their high resolution. They can produce very small displacements, on the order of nanometers, making them ideal for precision positioning applications. They also have a fast response time, allowing them to respond quickly to changes in the input voltage.

Another advantage of piezoelectric actuators is their energy efficiency. They consume very little power, making them ideal for battery-powered applications. They also generate very little heat, reducing the need for cooling systems.

Disadvantages

One of the main disadvantages of piezoelectric actuators is their limited displacement range. They can only produce small displacements, limiting their usefulness in applications that require large movements.

Another disadvantage is their sensitivity to temperature changes. The properties of piezoelectric materials can change with temperature, affecting the performance of the actuator. This requires careful design and control to ensure reliable operation.