Multifunctional Sensors

Introduction

Multifunctional sensors are advanced devices capable of detecting and responding to multiple physical, chemical, or biological stimuli. These sensors integrate various sensing capabilities into a single unit, offering enhanced functionality and efficiency in diverse applications. The development of multifunctional sensors is driven by the need for compact, cost-effective, and versatile solutions in fields such as healthcare, environmental monitoring, industrial automation, and consumer electronics.

Principles of Operation

Multifunctional sensors operate based on the integration of multiple sensing elements within a single platform. These elements can detect various parameters such as temperature, pressure, humidity, light, gas concentration, and biological markers. The integration is achieved through advanced materials, microfabrication techniques, and signal processing algorithms.

Sensing Mechanisms

Multifunctional sensors employ a variety of sensing mechanisms, including:

- **Piezoelectric Sensing:** Utilizes materials that generate an electric charge in response to mechanical stress. This mechanism is widely used in pressure and vibration sensors.

- **Optical Sensing:** Involves the detection of changes in light properties, such as intensity, wavelength, or polarization. Optical sensors are used for measuring parameters like light intensity, color, and chemical composition.

- **Electrochemical Sensing:** Based on the measurement of electrical signals resulting from chemical reactions. This mechanism is prevalent in gas sensors and biosensors.

- **Capacitive Sensing:** Detects changes in capacitance caused by variations in dielectric properties or distance between electrodes. Capacitive sensors are commonly used for touch and proximity detection.

Materials and Fabrication Techniques

The performance and capabilities of multifunctional sensors are heavily influenced by the materials used and the fabrication techniques employed.

Advanced Materials

- **Nanomaterials:** Nanostructured materials, such as carbon nanotubes and graphene, offer high surface area, excellent electrical conductivity, and mechanical strength, making them ideal for multifunctional sensors.

- **Smart Polymers:** These materials can change their properties in response to external stimuli, such as temperature or pH, enabling dynamic sensing capabilities.

- **Metal Oxides:** Widely used in gas sensors due to their high sensitivity and selectivity to various gases.

Fabrication Techniques

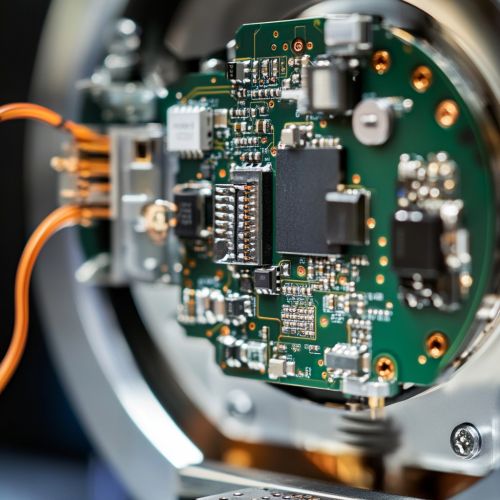

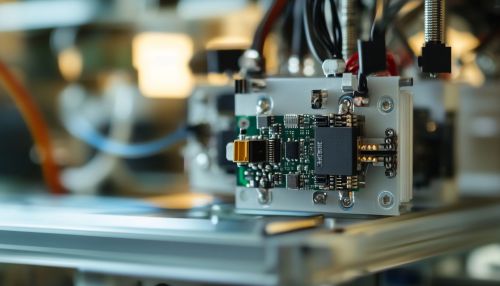

- **Microelectromechanical Systems (MEMS):** MEMS technology enables the miniaturization and integration of multiple sensing elements on a single chip, enhancing the functionality and reducing the size of sensors.

- **3D Printing:** Allows for the rapid prototyping and customization of sensor designs, facilitating the development of complex sensor architectures.

- **Thin-Film Deposition:** Techniques such as sputtering and chemical vapor deposition are used to create thin layers of sensing materials on substrates, crucial for optical and electrochemical sensors.

Applications

Multifunctional sensors have a wide range of applications across various industries due to their ability to simultaneously monitor multiple parameters.

Healthcare

In healthcare, multifunctional sensors are used for continuous monitoring of vital signs, such as heart rate, blood pressure, and oxygen saturation. They are also employed in wearable devices for tracking physical activity and detecting biomarkers for disease diagnosis.

Environmental Monitoring

These sensors play a critical role in environmental monitoring by detecting pollutants, measuring air and water quality, and assessing climate conditions. Their ability to provide real-time data on multiple environmental parameters is essential for effective environmental management.

Industrial Automation

In industrial settings, multifunctional sensors are used for process control, equipment monitoring, and safety applications. They enable the automation of complex processes by providing comprehensive data on temperature, pressure, humidity, and chemical composition.

Consumer Electronics

Multifunctional sensors are integral to the functionality of modern consumer electronics, such as smartphones and smart home devices. They enable features like touchscreens, motion detection, and voice recognition by integrating various sensing capabilities.

Challenges and Future Directions

Despite their advantages, multifunctional sensors face several challenges, including:

- **Complexity and Cost:** The integration of multiple sensing elements increases the complexity and cost of sensor design and manufacturing.

- **Interference and Cross-Sensitivity:** Multifunctional sensors may experience interference between different sensing elements, affecting their accuracy and reliability.

- **Data Processing:** The large volume of data generated by multifunctional sensors requires advanced data processing and analysis techniques to extract meaningful information.

Future research and development efforts are focused on addressing these challenges through the use of advanced materials, improved fabrication techniques, and innovative data processing algorithms. The continued evolution of multifunctional sensors is expected to drive significant advancements in various fields, offering new possibilities for monitoring and control.