Mechanical Sensors

Introduction

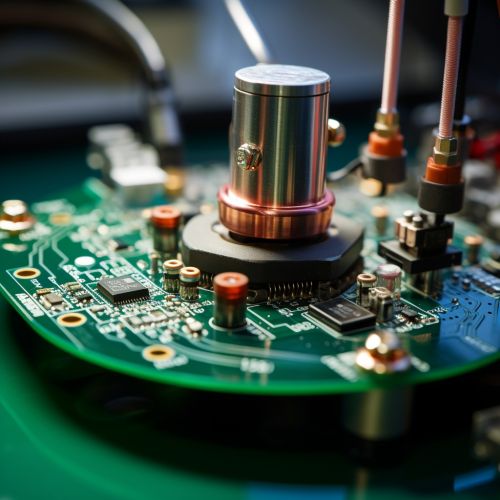

Mechanical sensors are devices that measure physical quantities such as pressure, temperature, force, acceleration, and others, and convert them into a readable output. They play a crucial role in a variety of fields, including industrial automation, automotive engineering, aerospace engineering, and biomedical engineering.

Types of Mechanical Sensors

There are several types of mechanical sensors, each designed to measure a specific physical quantity. These include:

- Strain gauges: These sensors measure the deformation or displacement of an object under force. They are commonly used in structural engineering to monitor buildings and bridges for signs of stress or damage.

- Accelerometers: These sensors measure acceleration forces. They are often used in automotive and aerospace applications to monitor the motion of vehicles.

- Thermocouples: These sensors measure temperature by exploiting the thermoelectric effect. They are widely used in industrial processes that require precise temperature control.

- Pressure sensors: These sensors measure the pressure of gases or liquids. They are commonly used in HVAC systems, industrial processes, and medical devices.

- Proximity sensors: These sensors detect the presence or absence of objects without physical contact. They are often used in automation and robotics.

Working Principle of Mechanical Sensors

Mechanical sensors work on the principle of transduction, which involves converting one form of energy into another. In the case of mechanical sensors, the physical quantity being measured is converted into an electrical signal that can be easily read and interpreted.

For example, a strain gauge works by changing its electrical resistance in response to the strain experienced by the object it's attached to. Similarly, an accelerometer measures acceleration forces by detecting changes in capacitance or piezoelectric effect, while a thermocouple measures temperature by generating a voltage proportional to the temperature difference between its two junctions.

Applications of Mechanical Sensors

Mechanical sensors have a wide range of applications across various industries. In industrial automation, they are used to monitor and control processes, ensuring they operate within specified parameters. In automotive engineering, they are used to monitor vehicle performance and enhance safety features. In aerospace engineering, they are used to monitor the structural integrity of aircraft and spacecraft. In biomedical engineering, they are used in a variety of medical devices to monitor patient health and assist in diagnosis and treatment.

Future Trends in Mechanical Sensors

With advancements in technology, mechanical sensors are becoming increasingly sophisticated. The trend is towards miniaturization, with sensors becoming smaller and more efficient. There is also a growing demand for wireless sensors, which offer greater flexibility and ease of installation. Furthermore, the advent of smart sensors, which can process and analyze the data they collect, is expected to revolutionize the field of mechanical sensing.