Lithium-Ion Battery Advancements

Introduction

Lithium-ion (Li-ion) batteries have revolutionized the world of portable electronics since their commercial introduction in 1991 by Sony. They are now the power source of choice for a wide range of applications, from mobile phones and laptops to electric vehicles and grid energy storage. This article explores the advancements in lithium-ion battery technology, focusing on the developments in materials, design, and manufacturing processes that have contributed to their improved performance, safety, and cost-effectiveness.

Materials Advancements

The performance of a lithium-ion battery is largely determined by the materials used in its construction. The choice of electrode materials, in particular, has a significant impact on the battery's energy density, power density, charge/discharge rate, lifespan, and safety.

Cathode Materials

The cathode, or positive electrode, of a lithium-ion battery is typically made from a lithium metal oxide. The most common cathode materials in the early lithium-ion batteries were lithium cobalt oxide (LiCoO2) and lithium iron phosphate (LiFePO4). However, recent advancements have led to the development of new cathode materials that offer improved performance and safety.

One such advancement is the use of nickel-based cathode materials, such as lithium nickel manganese cobalt oxide (NMC) and lithium nickel cobalt aluminum oxide (NCA). These materials offer higher energy density and better thermal stability than traditional cathode materials, making them ideal for high-energy applications like electric vehicles.

Anode Materials

The anode, or negative electrode, of a lithium-ion battery is typically made from carbon-based materials, with graphite being the most common. However, recent advancements have led to the development of new anode materials that offer higher energy density and faster charge/discharge rates.

One such advancement is the use of silicon-based anode materials. Silicon has a much higher lithium storage capacity than graphite, allowing for a significant increase in energy density. However, silicon anodes suffer from a high volume expansion during charging, which can lead to mechanical degradation and a shorter battery life. Recent research has focused on addressing this issue, with promising results from the use of silicon-carbon composites and nanostructured silicon.

Design Advancements

Advancements in lithium-ion battery design have also played a crucial role in improving their performance and safety. These advancements include the development of new cell architectures, the use of advanced separator materials, and the implementation of sophisticated battery management systems.

Cell Architecture

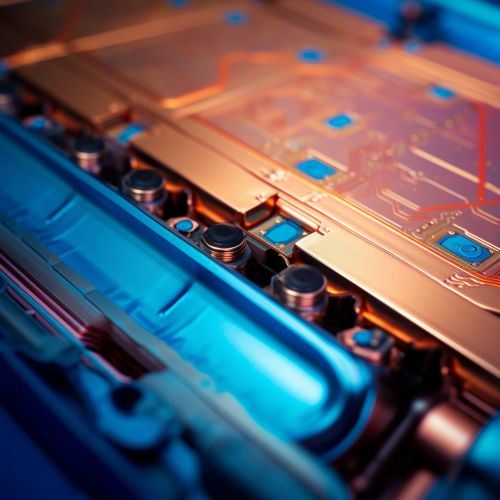

The cell architecture of a lithium-ion battery refers to the arrangement of its internal components. The most common cell architectures are the cylindrical cell, the prismatic cell, and the pouch cell. Each of these architectures has its advantages and disadvantages, and the choice of architecture depends on the specific requirements of the application.

Recent advancements in cell architecture have focused on increasing the energy density and improving the thermal management of lithium-ion batteries. For example, the development of high-energy-density cylindrical cells with a 'tabless' design, which reduces internal resistance and improves heat dissipation.

Separator Materials

The separator in a lithium-ion battery is a critical component that prevents direct contact between the anode and cathode, which could lead to a short circuit and potentially a thermal runaway reaction. The separator also allows for the transport of lithium ions between the electrodes during charging and discharging.

Advancements in separator materials have focused on improving their thermal stability, mechanical strength, and ionic conductivity. For example, the development of ceramic-coated separators, which offer improved safety by preventing the separator from shrinking or melting at high temperatures.

Battery Management Systems

A battery management system (BMS) is an electronic system that manages a lithium-ion battery pack. The BMS monitors the battery's state, calculates secondary data, controls its environment, and protects the battery from operating outside its safe operating area.

Advancements in BMS technology have led to improved battery performance, lifespan, and safety. For example, the development of advanced algorithms for state-of-charge (SOC) and state-of-health (SOH) estimation, which allows for more accurate monitoring and control of the battery.

Manufacturing Advancements

Advancements in lithium-ion battery manufacturing processes have contributed to their improved performance and cost-effectiveness. These advancements include the development of high-speed, high-precision manufacturing equipment, the implementation of advanced quality control methods, and the adoption of sustainable manufacturing practices.

Manufacturing Equipment

The manufacturing of lithium-ion batteries involves several complex processes, including electrode preparation, cell assembly, formation, and aging. The performance and safety of the finished battery are highly dependent on the precision and speed of these processes.

Advancements in manufacturing equipment have led to increased production efficiency and improved battery quality. For example, the development of high-speed coating machines for electrode preparation, which allows for a more uniform and precise coating of the electrode materials.

Quality Control Methods

Quality control in lithium-ion battery manufacturing is crucial to ensure the performance and safety of the finished product. This involves the inspection and testing of the raw materials, the intermediate products, and the finished battery.

Advancements in quality control methods have led to improved battery reliability and reduced manufacturing costs. For example, the implementation of advanced inspection systems, such as machine vision and X-ray inspection, which allows for more accurate detection of defects.

Sustainable Manufacturing Practices

The manufacturing of lithium-ion batteries has a significant environmental impact, due to the energy-intensive nature of the processes and the use of hazardous materials. Therefore, the adoption of sustainable manufacturing practices is crucial to reduce this impact.

Advancements in sustainable manufacturing practices include the development of energy-efficient manufacturing processes, the use of green materials, and the implementation of battery recycling programs. For example, the adoption of dry electrode manufacturing, which eliminates the need for toxic solvents and reduces energy consumption.

Conclusion

The advancements in lithium-ion battery technology have led to significant improvements in their performance, safety, and cost-effectiveness. These advancements are the result of ongoing research and development efforts in materials science, battery design, and manufacturing processes. As the demand for high-performance, safe, and affordable lithium-ion batteries continues to grow, further advancements in these areas are expected.