Leather Production

Leather Production

Leather production is a complex and multifaceted process that transforms raw animal hides into durable and versatile material used in various industries, including fashion, upholstery, and automotive. This article delves into the intricate steps involved in leather production, exploring the scientific and technical aspects that ensure the quality and functionality of the final product.

Raw Material Acquisition

The primary raw material for leather production is animal hides, predominantly sourced from cattle, sheep, goats, and pigs. These hides are by-products of the meat industry, ensuring that leather production is an efficient use of resources. The quality of the hide is crucial and depends on factors such as the animal's age, breed, diet, and living conditions.

- Preservation of Hides

Immediately after slaughter, hides must be preserved to prevent decomposition. The most common preservation methods include salting and drying. Salting involves applying a layer of salt to the hide, which draws out moisture and inhibits bacterial growth. Drying, on the other hand, involves air-drying the hides in controlled environments to reduce moisture content.

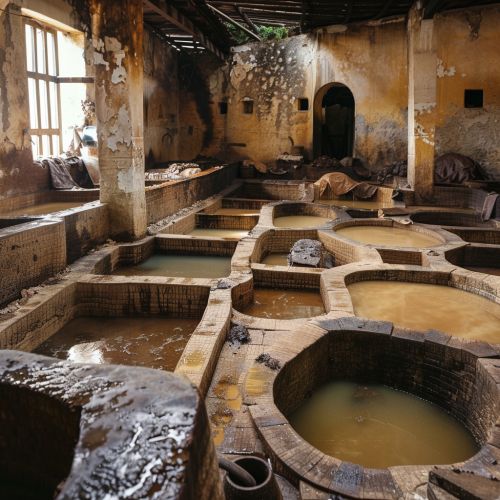

Tanning Process

Tanning is the core process in leather production, converting raw hides into stable and non-putrescible leather. This process can be divided into several stages:

Pre-Tanning

Pre-tanning prepares the hides for the tanning process and includes several steps:

- **Soaking:** Hides are soaked in water to rehydrate and clean them of dirt, blood, and salt.

- **Liming:** Hides are treated with a lime solution to remove hair, epidermis, and other unwanted proteins.

- **Fleshing:** Mechanical removal of excess flesh and fat from the hides.

- **Deliming:** Neutralizing the alkaline condition of the hides using acids or ammonium salts.

- **Bating:** Enzymatic treatment to further clean and soften the hides.

- **Pickling:** Lowering the pH of the hides using a solution of salt and acid to prepare them for tanning.

Tanning

The tanning process stabilizes the collagen fibers in the hide, making them resistant to decomposition. There are several tanning methods:

- **Vegetable Tanning:** Uses natural tannins extracted from plant materials such as bark, leaves, and fruits. This method produces firm and durable leather, often used for saddlery and belts.

- **Chrome Tanning:** Utilizes chromium salts, primarily chromium sulfate, to produce soft and pliable leather. This method is faster and more efficient than vegetable tanning and is widely used in the production of footwear and garments.

- **Aldehyde Tanning:** Employs aldehydes, such as glutaraldehyde, to produce white leather, often used in medical and automotive applications.

- **Synthetic Tanning:** Uses synthetic tanning agents, such as phenols and naphthalenes, to produce leather with specific properties.

Post-Tanning Operations

After tanning, the leather undergoes several post-tanning operations to enhance its properties and appearance:

- **Neutralization:** Adjusting the pH of the leather to a neutral level.

- **Retanning:** Additional tanning to impart specific characteristics, such as softness or water resistance.

- **Dyeing:** Coloring the leather using various dyes to achieve the desired hue.

- **Fatliquoring:** Adding oils and fats to lubricate the fibers and enhance flexibility and softness.

- **Drying:** Removing excess moisture through various drying methods, such as air drying, vacuum drying, or toggling.

- **Staking:** Mechanically softening the leather by stretching and flexing.

- **Buffing:** Sanding the surface to achieve a smooth finish.

- **Finishing:** Applying surface treatments, such as coatings, embossing, or polishing, to enhance the leather's appearance and performance.

Quality Control

Quality control is a critical aspect of leather production, ensuring that the final product meets industry standards and customer expectations. This involves rigorous testing of various parameters, including:

- **Thickness:** Measured using micrometers to ensure uniformity.

- **Tensile Strength:** Assessed through tensile testing to determine the leather's strength and durability.

- **Flexibility:** Evaluated through flex testing to ensure the leather can withstand repeated bending without cracking.

- **Color Fastness:** Tested to ensure the dye remains stable and does not fade or bleed.

- **Water Resistance:** Assessed through water absorption and penetration tests.

Environmental Impact

Leather production has significant environmental implications, primarily due to the chemicals used in the tanning process and the large volumes of water required. Efforts to mitigate these impacts include:

- **Waste Management:** Proper disposal and treatment of solid and liquid waste to prevent environmental contamination.

- **Water Recycling:** Implementing water recycling systems to reduce water consumption.

- **Eco-Friendly Tanning:** Developing and using alternative tanning methods that minimize the use of harmful chemicals.

Innovations in Leather Production

Recent advancements in leather production focus on sustainability and efficiency. Innovations include:

- **Bio-Based Tanning Agents:** Research into natural and renewable tanning agents to replace traditional chemicals.

- **Closed-Loop Systems:** Implementing closed-loop systems to recycle waste and reduce environmental impact.

- **Synthetic Leather:** Development of high-quality synthetic leather alternatives, such as polyurethane and microfiber, to reduce reliance on animal hides.