Laser-Assisted Bioprinting

Introduction

Laser-assisted bioprinting (LAB) is a branch of bioprinting that utilizes laser energy to create patterns of living cells. This technology is a form of additive manufacturing that uses cellular materials as building blocks to fabricate complex biological structures. The goal of LAB is to create functional biological structures that can be used for tissue engineering and regenerative medicine.

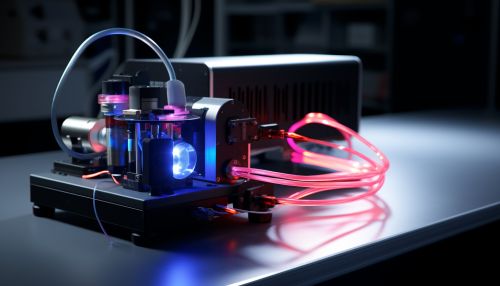

Principle of Operation

The operation of LAB is based on the principle of laser-induced forward transfer (LIFT). In this process, a pulsed laser beam is focused onto a ribbon, which consists of a layer of biological material (bio-ink) on top of an energy absorbing layer. The energy from the laser causes rapid local heating, which leads to the formation of a high-pressure bubble that propels a droplet of bio-ink onto a receiving substrate. The droplets of bio-ink are then assembled layer by layer to create a three-dimensional (3D) structure.

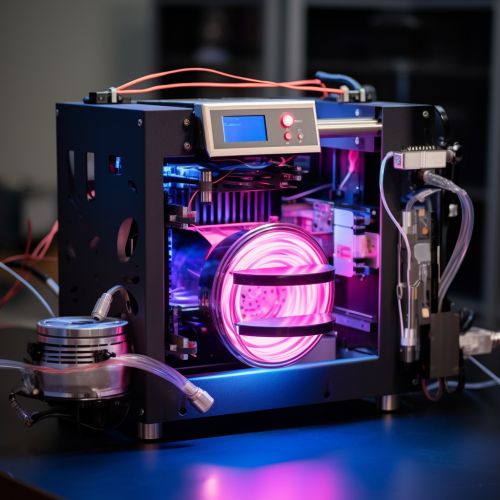

Components of a Laser-Assisted Bioprinter

A typical LAB system consists of three main components: a pulsed laser source, a ribbon, and a receiving substrate. The laser source generates a pulsed laser beam that is used to transfer the bio-ink. The ribbon is a thin film that contains the bio-ink and an energy absorbing layer. The receiving substrate is where the bio-ink droplets are collected and assembled into a 3D structure.

Bio-Ink

The bio-ink used in LAB is a suspension of living cells in a suitable medium. The choice of cells depends on the specific application. For example, for skin tissue engineering, the bio-ink may contain keratinocytes and fibroblasts. The medium provides the necessary nutrients for the cells and also acts as a carrier for the cells during the printing process.

Applications

LAB has a wide range of applications in the field of tissue engineering and regenerative medicine. It can be used to fabricate complex biological structures such as skin, bone, cartilage, and blood vessels. It can also be used for the production of organ-on-a-chip systems, which are miniaturized models of human organs that can be used for drug testing and disease modeling.

Advantages and Limitations

One of the main advantages of LAB is its high resolution, which allows for the fabrication of structures with intricate details. It also allows for precise control over the spatial distribution of cells, which is important for creating functional tissues. However, LAB also has some limitations. The process can be slow, especially for large structures. In addition, the bio-ink needs to have certain properties, such as appropriate viscosity and cell density, for successful printing.

Future Perspectives

The field of LAB is still in its early stages, and there is much room for improvement and innovation. Future research will likely focus on improving the speed and efficiency of the printing process, developing new types of bio-ink, and exploring new applications.