Ionic Polymer-Metal Composites

Introduction

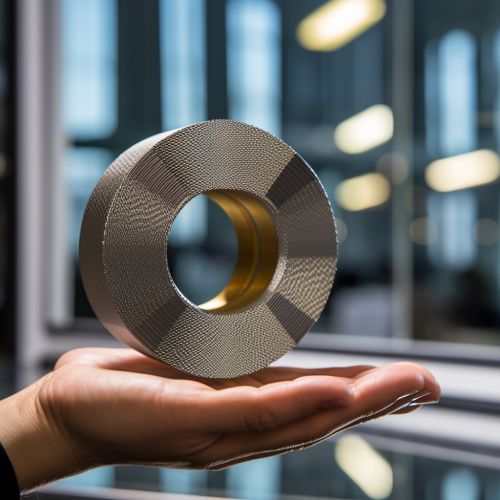

Ionic Polymer-Metal Composites (IPMCs) are a class of electroactive polymers that exhibit unique characteristics, such as large deformation under low voltage stimulation. They are composed of an ionic polymer base, typically Nafion or Flemion, which is plated with a noble metal such as gold or platinum. This combination of materials results in a composite that can act as both a sensor and an actuator, making it a valuable tool in the field of soft robotics and biomedical engineering.

Structure and Fabrication

The structure of an IPMC is primarily composed of an ionic polymer membrane, which is chemically plated with a noble metal. This process, known as electroless plating, involves the reduction of metal ions in a solution to form a metal coating on the polymer surface. The ionic polymer membrane serves as a flexible, conductive backbone, while the metal plating provides the necessary electrical conductivity for the composite to function as an actuator or sensor.

Properties

IPMCs have several unique properties that make them ideal for use in a variety of applications. These include large deformation under low voltage stimulation, the ability to operate in aqueous environments, and the ability to act as both sensors and actuators. These properties are a result of the unique combination of the ionic polymer and the metal plating, which work together to create a composite that is both flexible and conductive.

Applications

IPMCs have a wide range of applications, particularly in the fields of soft robotics and biomedical engineering. In soft robotics, they can be used to create flexible, lightweight robots that can move and adapt to their environment in ways that traditional robots cannot. In biomedical engineering, they can be used to create devices such as artificial muscles and actuators for minimally invasive surgery.

Challenges and Future Directions

While IPMCs have many promising applications, there are also several challenges that must be overcome in order to fully realize their potential. These include issues related to durability, repeatability, and control. Despite these challenges, the field of IPMC research is rapidly advancing, and there are many exciting opportunities for future development.