Fractional distillation

Introduction

Fractional distillation is a specialized method of distillation used in separating mixtures of liquids that have different boiling points. This technique is commonly applied in laboratories and industrial processes such as the refining of crude oil into gasoline.

Principles of Fractional Distillation

The principle behind fractional distillation is that different liquids boil at different temperatures. When a mixture of liquids is heated, the liquid with the lowest boiling point will vaporize first. The vapor is then condensed and collected separately from the original mixture. This process is repeated until all the liquids in the mixture have been separated.

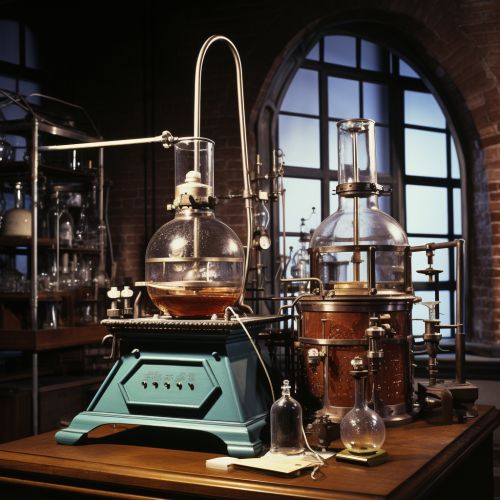

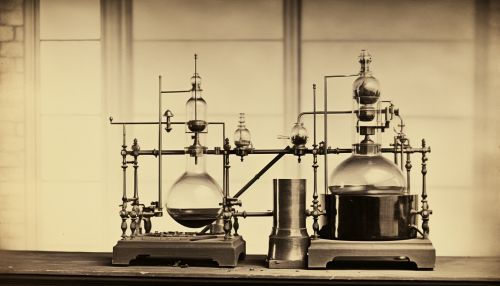

Equipment Used in Fractional Distillation

The equipment used in fractional distillation includes a distillation flask, a fractionating column, a condenser, and a receiver. The distillation flask is where the liquid mixture is heated. The fractionating column is a long, narrow tube that provides a large surface area for the vapor to condense on. The condenser cools the vapor back into a liquid, which is then collected in the receiver.

Process of Fractional Distillation

The process of fractional distillation begins with the liquid mixture being heated in the distillation flask. As the temperature rises, the liquid with the lowest boiling point begins to vaporize. The vapor rises up the fractionating column, where it condenses on the large surface area provided by the column. As the temperature continues to rise, the next liquid with a higher boiling point begins to vaporize and follows the same process. This cycle continues until all the liquids have been separated.

Applications of Fractional Distillation

Fractional distillation has a wide range of applications in various industries. In the petroleum industry, it is used to separate crude oil into its various components, such as gasoline, diesel fuel, and lubricating oil. In the chemical industry, it is used to purify chemicals and to separate mixtures of chemicals. In the food and beverage industry, it is used to concentrate and purify alcoholic beverages.

Advantages and Disadvantages of Fractional Distillation

Fractional distillation has several advantages over simple distillation. It is more efficient at separating mixtures of liquids and can separate liquids with very close boiling points. However, it also has some disadvantages. The equipment used in fractional distillation is more complex and expensive than that used in simple distillation. The process also requires more energy and time.

Conclusion

Fractional distillation is a crucial technique in many industries, from petroleum refining to food and beverage production. Despite its disadvantages, its ability to efficiently separate mixtures of liquids makes it an invaluable tool in these fields.