Electrostatic discharge

Introduction

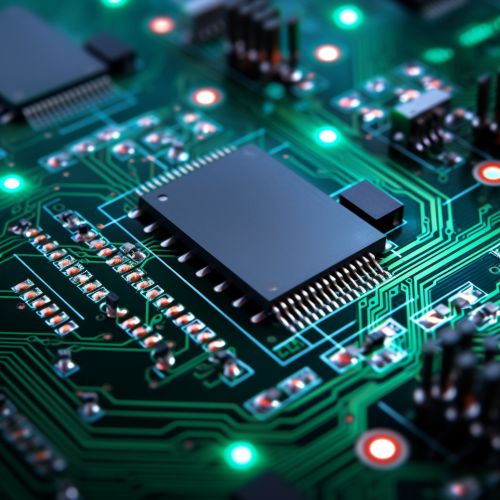

Electrostatic discharge (ESD) is a sudden and momentary electric current that flows between two objects at different electrical potentials. The term is usually used in the electronics and other industries to describe momentary unwanted currents that may cause damage to electronic equipment. ESD is a serious issue in solid state electronics, such as integrated circuits. Integrated circuits are made from semiconductor materials such as silicon and insulating materials such as silicon dioxide. Either of these materials can suffer permanent damage when subjected to high voltages.

Causes of Electrostatic Discharge

ESD can be caused by a buildup of static electricity. Static electricity is often generated through tribocharging, the separation of electrical charges that occurs when two materials are brought into contact and then separated. Examples of tribocharging include walking on a rug, rubbing a plastic comb against dry hair, rubbing a balloon against a sweater, ascending from a fabric car seat, or removing some types of plastic packaging. In all these cases, the friction between two materials results in tribocharging, thus creating a difference of electrical potential that can lead to an ESD event.

Another cause of ESD damage is through electrostatic induction. This occurs when an electrically charged object is placed near a conductive object isolated from the ground. The presence of the charged object creates an electrostatic field that causes electrical charges on the surface of the other object to redistribute. This can create a very high voltage that leads to ESD.

Effects of Electrostatic Discharge

ESD can cause a range of harmful effects, particularly in the electronics industry. These can include damage to electronic components, fires and explosions in flammable environments, and injury to personnel.

In the electronics industry, ESD can lead to catastrophic failure of the affected device, or latent damage that may not immediately affect the device's functionality but can cause it to fail prematurely. In addition, ESD can cause data corruption in solid state memory devices.

ESD Control

ESD control is a critical part of electronics manufacturing. The aim is to avoid the buildup of static electricity and prevent ESD events. This can be achieved through a variety of means, including controlling the environment, using ESD-safe materials and equipment, and following proper procedures.

Control of the environment often involves maintaining a relative humidity level of at least 40%. Dry air increases the likelihood of static charge generation, so by maintaining a certain level of humidity, the risk of ESD can be reduced.

In addition, surfaces that come into contact with electronic components are often made of ESD-safe materials. These materials are designed to dissipically conduct static charges, preventing the buildup of static electricity.

Procedures for handling electronic components also play a critical role in ESD control. These can include grounding personnel and equipment, using antistatic bags for storing and transporting components, and implementing a comprehensive ESD control program.

ESD Standards and Models

There are several standards and models used to describe and predict ESD events, and to design ESD-safe environments. These include the Human Body Model (HBM), the Charged Device Model (CDM), and the Machine Model (MM). Each of these models represents a different source of ESD and is used to design different aspects of an ESD-safe environment.