Copper indium gallium selenide

Introduction

Copper indium gallium selenide (CIGS) is a type of semiconductor material used in the production of solar cells. It is a tetrahedrally bonded semiconductor, with the chalcopyrite crystal structure. The material is a solid solution of copper indium selenide (CIS) and copper gallium selenide, with a chemical formula of CuInxGa(1-x)Se2.

Composition and Structure

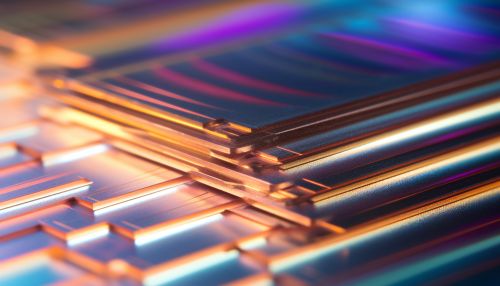

CIGS is composed of copper, indium, gallium, and selenium. The ratio of gallium to (indium + gallium) can vary from 0 (pure CIS) to 1 (pure CGS). The material's bandgap can be tuned by adjusting the ratio of gallium to indium, which makes it highly suitable for use in multi-junction solar cells. The chalcopyrite crystal structure of CIGS is a derivative of the zinc blende structure, with a tetragonal unit cell.

Properties

CIGS has several properties that make it an attractive material for solar cell applications. It has a high absorption coefficient, which means that it can absorb sunlight very efficiently. It also has a direct bandgap, which means that it can convert sunlight into electricity more efficiently than materials with an indirect bandgap. Furthermore, CIGS has a relatively high tolerance to defects, which makes it less sensitive to impurities and other manufacturing imperfections.

Fabrication

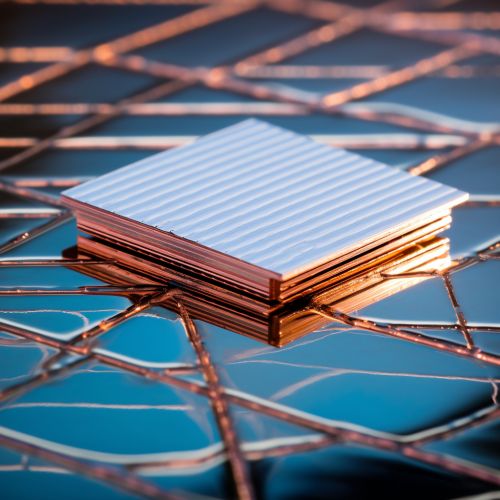

CIGS solar cells are typically fabricated using thin-film deposition techniques. The most common method is co-evaporation, where copper, indium, gallium, and selenium are simultaneously evaporated onto a substrate. Other methods include sputtering, electroplating, and non-vacuum methods such as nanoparticle ink-based processes. The choice of fabrication method can significantly impact the performance and cost of the resulting solar cells.

Applications

The primary application of CIGS is in the production of thin-film solar cells. These solar cells have several advantages over traditional silicon-based solar cells, including lower cost, lighter weight, and better performance in low-light conditions. CIGS solar cells can be used in a variety of applications, including rooftop solar panels, building-integrated photovoltaics, and portable power systems.

Challenges and Future Directions

Despite its many advantages, CIGS also faces several challenges. These include the scarcity and cost of indium, the complexity of the fabrication process, and the need for further improvements in efficiency and stability. Ongoing research is focused on addressing these challenges and further improving the performance and cost-effectiveness of CIGS solar cells.