Compression Testing

Introduction

Compression testing is a method used in material science to determine the behavior of materials under compressive load. This type of testing is critical in the fields of structural engineering, mechanical engineering, and materials science. It provides valuable data about a material's ability to withstand compressive forces, its elasticity, and its limits of deformation before failure.

Principles of Compression Testing

Compression testing operates on the principle of applying a compressive force or load on a material and observing its response. The test measures the material's deformation (change in shape) under the applied force, which is typically recorded on a stress-strain curve. This curve provides essential information about the material's mechanical properties, such as its yield strength, ultimate strength, and modulus of elasticity.

Types of Compression Tests

There are several types of compression tests, each designed to evaluate different aspects of a material's compressive properties.

Static Compression Test

In a static compression test, the load is applied slowly and steadily until the material fails or deforms. This test provides information about the material's behavior under a constant load, which is useful in applications where the material is expected to bear a constant weight or pressure.

Dynamic Compression Test

A dynamic compression test involves applying a rapidly changing load to the material. This test is used to evaluate a material's behavior under impact or sudden load changes, which is critical in industries such as automotive and aerospace, where materials must withstand high-impact forces.

Fatigue Compression Test

A fatigue compression test subjects the material to repeated compressive loads to determine its durability and lifespan. This test is essential in industries where materials are subjected to continuous or cyclic loads, such as in bridges, buildings, and machinery parts.

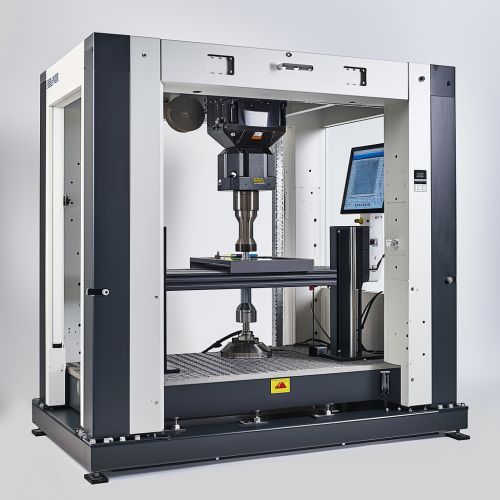

Equipment Used in Compression Testing

Compression testing requires specialized equipment known as a compression testing machine. This machine consists of a load frame that can apply a compressive force, a load cell to measure the applied force, and a deformation measuring device to record the material's deformation under the applied load.

Applications of Compression Testing

Compression testing has a wide range of applications across various industries.

Construction and Civil Engineering

In the construction and civil engineering industry, compression testing is used to test the strength of materials like concrete, brick, and stone. These materials are subjected to compressive forces in structures, and their ability to withstand these forces is crucial to the safety and longevity of the structures.

Automotive Industry

In the automotive industry, compression testing is used to test the strength and durability of various car parts, such as engine components, body panels, and tires. The results of these tests help in the design and manufacturing of safer and more durable vehicles.

Aerospace Industry

In the aerospace industry, compression testing is used to test the strength and durability of materials used in aircraft and spacecraft. These materials must withstand high compressive forces during takeoff, flight, and landing, making compression testing critical in ensuring the safety and reliability of these vehicles.