Coating Material

Introduction

Coating materials are substances applied to surfaces to improve their functional or aesthetic properties. They play a crucial role in a wide range of industries, from construction and automotive to electronics and aerospace.

Types of Coating Materials

Coating materials can be broadly classified into three categories: organic, inorganic, and hybrid.

Organic Coatings

Organic coatings are primarily composed of organic polymers and resins. They include paints, varnishes, and lacquers. Organic coatings are popular for their versatility and ease of application.

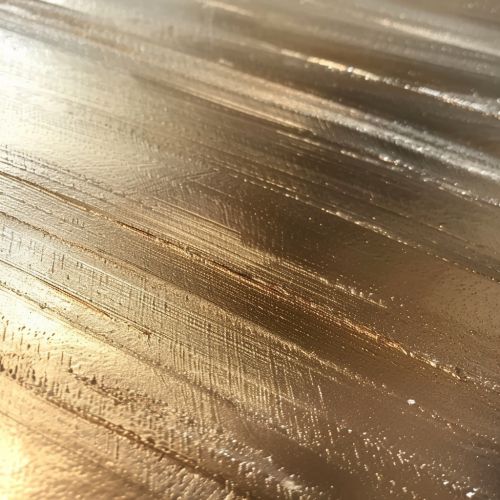

Inorganic Coatings

Inorganic coatings, such as ceramic or metallic coatings, are known for their high-temperature resistance and durability. They are often used in industrial applications where high performance is required.

Hybrid Coatings

Hybrid coatings combine the properties of both organic and inorganic materials to create coatings with unique characteristics. An example of a hybrid coating is a sol-gel coating, which uses a combination of organic and inorganic chemistry.

Properties of Coating Materials

The properties of coating materials can vary widely depending on their composition and application. However, some common properties include:

Adhesion

The ability of a coating to stick to the substrate is known as adhesion. Good adhesion is crucial for the performance of the coating.

Hardness

Hardness refers to the resistance of a coating to penetration or scratching. It is an important property for coatings used in high-wear applications.

Flexibility

Flexibility is the ability of a coating to bend or flex without cracking or losing adhesion. This is particularly important for coatings applied to flexible substrates.

Chemical Resistance

Chemical resistance is the ability of a coating to resist damage from exposure to chemicals. This is a critical property for coatings used in harsh environments.

Applications of Coating Materials

Coating materials find use in a wide range of applications, each with its own set of requirements and challenges.

Protective Coatings

Protective coatings are used to protect surfaces from environmental factors such as moisture, UV radiation, and chemical exposure. Examples include anti-corrosion coatings for metal surfaces and UV-resistant coatings for outdoor applications.

Decorative Coatings

Decorative coatings are used to enhance the appearance of a surface. They can provide color, gloss, and texture to a substrate. Examples include paint for buildings and varnish for furniture.

Functional Coatings

Functional coatings are used to provide a specific functionality to a surface. This can include anti-reflective coatings for optical devices, non-stick coatings for cookware, and conductive coatings for electronic devices.

Future Trends

The field of coating materials is continually evolving, with new materials and technologies being developed to meet the changing needs of industry and society. Some emerging trends include:

Nanotechnology

Nanotechnology is being used to develop coatings with enhanced properties. For example, nanocoatings can provide superior resistance to wear, corrosion, and heat.

Green Coatings

With increasing environmental awareness, there is a growing demand for green coatings. These are coatings that are environmentally friendly, either in their production, use, or disposal.

Smart Coatings

Smart coatings are coatings that can respond to changes in their environment. For example, self-healing coatings can repair themselves when damaged, while thermochromic coatings can change color with temperature.