Ceramic capacitor

Introduction

A ceramic capacitor is a fixed-value capacitor in which ceramic material acts as the dielectric. It is constructed of two or more alternating layers of ceramic and a metal layer acting as the electrodes. The composition of the ceramic material defines the electrical behavior and therefore applications.

Structure and Composition

Ceramic capacitors are typically made up of a ceramic dielectric and a metal electrode. The ceramic material, which is a type of ceramic material, is sandwiched between two layers of metal, which act as the electrodes. The ceramic material is typically a mixture of titanium dioxide and other materials, which are mixed together and then heated to form a ceramic. The metal electrodes are typically made of a material such as silver or copper.

Types of Ceramic Capacitors

There are several types of ceramic capacitors, including disc ceramic capacitors, multilayer ceramic capacitors (MLCC), and ceramic power capacitors. Each type has its own unique characteristics and applications.

Disc Ceramic Capacitors

Disc ceramic capacitors are the simplest type of ceramic capacitor. They are made by coating a ceramic disc with silver or copper on both sides. The disc is then encapsulated in a protective coating to prevent damage.

Multilayer Ceramic Capacitors (MLCC)

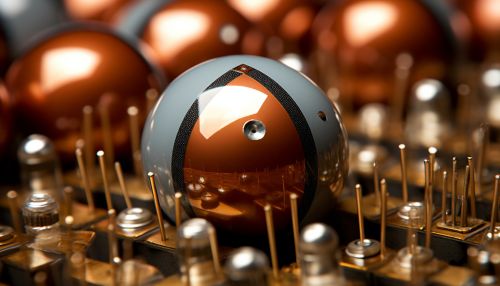

Multilayer ceramic capacitors (MLCC) are made by stacking multiple layers of ceramic and metal electrodes. This design allows for a higher capacitance value in a smaller physical size. MLCCs are commonly used in electronic devices due to their small size and high capacitance.

Ceramic Power Capacitors

Ceramic power capacitors are designed for high voltage applications. They are made with a ceramic dielectric that has a high breakdown voltage, allowing them to handle higher voltages than other types of ceramic capacitors.

Applications

Ceramic capacitors are used in a wide range of applications due to their versatility. They are commonly used in electronics such as radios, televisions, and computers, where they are used to filter noise and stabilize voltage and power levels. They are also used in power supply units, where they help to smooth out fluctuations in the power supply.

Advantages and Disadvantages

Ceramic capacitors have several advantages over other types of capacitors. They are small in size, making them ideal for use in compact electronic devices. They also have a high dielectric constant, which allows them to store a large amount of charge. Furthermore, they have a wide temperature range, making them suitable for use in a variety of environments.

However, ceramic capacitors also have some disadvantages. They have a lower voltage rating than other types of capacitors, which means they cannot be used in high voltage applications. They also have a relatively high equivalent series resistance (ESR), which can lead to energy loss.