Brayton Cycle

Overview

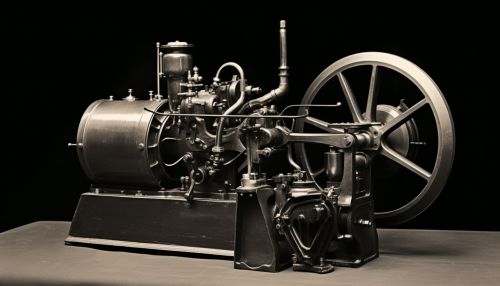

The Brayton cycle, also known as the Joule cycle, is a thermodynamic cycle that describes the workings of a constant pressure heat engine. The cycle is named after George Brayton, an American engineer who developed it in the late 19th century. It is characterized by a working fluid that is compressed, heated, and then expanded to do work on the surroundings.

Basic Principles

The Brayton cycle consists of four main processes: adiabatic compression, constant pressure heating, adiabatic expansion, and constant pressure cooling.

1. Adiabatic Compression: The working fluid, typically air, is drawn into the compressor where it is compressed adiabatically, i.e., without heat transfer. This process increases the pressure and temperature of the air but keeps the entropy constant.

2. Constant Pressure Heating: The compressed air is then passed through a combustion chamber where fuel is burned, adding heat to the air at constant pressure. This process increases the temperature and entropy of the air.

3. Adiabatic Expansion: The high-pressure, high-temperature air is then expanded adiabatically in a turbine. This process decreases the pressure and temperature of the air, but the entropy remains constant. The work done by the turbine is used to drive the compressor and any excess can be used to do useful work.

4. Constant Pressure Cooling: The expanded air is then cooled at constant pressure in a heat exchanger before being released to the surroundings or recirculated back into the compressor. This process decreases the temperature and entropy of the air.

Efficiency

The thermal efficiency of the Brayton cycle is given by the ratio of the net work output to the heat input. It is dependent on the compression ratio and the specific heat capacities of the working fluid. The efficiency can be improved by increasing the compression ratio, increasing the maximum temperature, or using a working fluid with a high specific heat capacity.

Applications

The Brayton cycle is commonly used in gas turbine engines, such as those found in power plants, jet engines, and ships. It is also used in some types of refrigeration systems.