Boron Nitride Nanotubes

Introduction

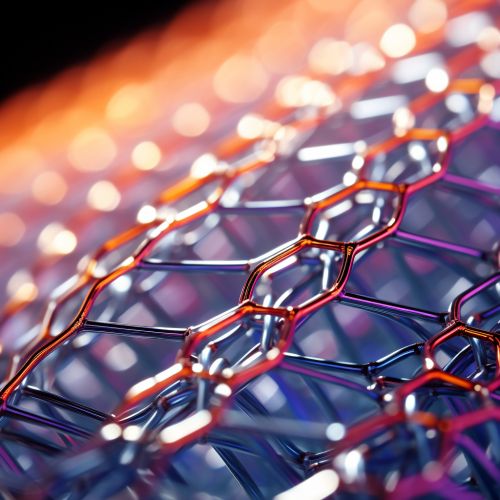

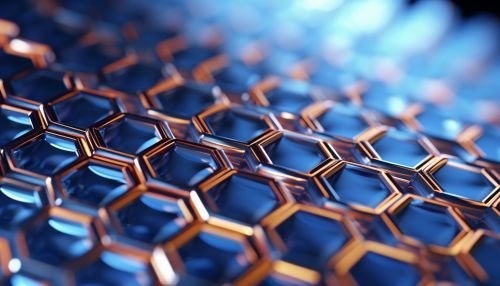

Boron nitride nanotubes (BNNTs) are a type of nanotube that are structurally analogous to carbon nanotubes. They are made up of alternating boron and nitrogen atoms, arranged in a hexagonal pattern. BNNTs are known for their exceptional mechanical, thermal, and electrical properties, which make them suitable for a wide range of applications in the fields of nanotechnology, materials science, and physics.

Structure and Properties

BNNTs are cylindrical structures with diameters typically in the range of 1-100 nanometers and lengths up to several micrometers. The walls of the nanotubes are composed of hexagonal boron nitride (h-BN) sheets, which are rolled up to form the tubular structure. This configuration gives BNNTs a unique combination of properties, including high thermal stability, excellent mechanical strength, and good electrical insulation.

The structure of BNNTs is similar to that of carbon nanotubes, with the key difference being the alternating boron and nitrogen atoms in BNNTs, as opposed to the carbon atoms in carbon nanotubes. This results in a more uniform distribution of electrical charge in BNNTs, which contributes to their superior thermal and electrical properties.

Synthesis Methods

There are several methods for synthesizing BNNTs, including chemical vapor deposition (CVD), arc discharge, and ball milling. Each method has its own advantages and disadvantages, and the choice of method depends on the specific requirements of the application.

Chemical vapor deposition (CVD) is a common method for BNNT synthesis. In this process, boron and nitrogen precursors are introduced into a reaction chamber, where they react at high temperatures to form BNNTs. The CVD method allows for good control over the size and structure of the BNNTs, but it can be expensive and requires specialized equipment.

Arc discharge is another method for BNNT synthesis. In this process, an electric arc is used to vaporize a boron-nitrogen target, and the resulting vapor is condensed to form BNNTs. The arc discharge method can produce BNNTs with a high degree of purity, but it is less controllable than the CVD method and can result in a wide range of nanotube sizes.

Ball milling is a mechanical method for BNNT synthesis. In this process, boron and nitrogen powders are ground together in a ball mill to form BNNTs. The ball milling method is relatively simple and inexpensive, but it can result in BNNTs with a wide range of sizes and structures.

Applications

Due to their unique properties, BNNTs have potential applications in a wide range of fields. Some of the most promising areas of application include electronics, thermal management, and structural composites.

In electronics, BNNTs can be used as insulating layers in devices such as transistors and capacitors. Their high thermal conductivity and electrical insulation properties make them ideal for this purpose.

In thermal management, BNNTs can be used to improve the thermal performance of materials and devices. Their high thermal conductivity allows them to efficiently conduct heat away from hot spots, which can help to prevent overheating and improve the reliability of electronic devices.

In structural composites, BNNTs can be used to enhance the mechanical properties of materials. Their high strength and stiffness can significantly improve the mechanical performance of composites, making them suitable for use in high-performance applications such as aerospace and automotive engineering.