Biocompatible materials

Introduction

Biocompatible materials are substances that can interact with living tissues without causing any adverse reactions. These materials are often used in medical devices and implants, such as heart valves, dental implants, and artificial joints. The concept of biocompatibility is critical in the field of biomaterials, as it ensures the safety and effectiveness of medical devices when they are implanted in the human body.

Types of Biocompatible Materials

There are several types of biocompatible materials, each with unique properties that make them suitable for specific applications. These include metals, ceramics, polymers, and composites.

Metals

Metals are often used in biocompatible materials due to their strength and durability. Examples of biocompatible metals include stainless steel, titanium, and cobalt-chromium alloys. These metals are commonly used in orthopedic implants, dental implants, and cardiovascular devices.

Ceramics

Ceramics are also used in biocompatible materials due to their hardness, wear resistance, and chemical stability. Examples of biocompatible ceramics include alumina, zirconia, and hydroxyapatite. These ceramics are commonly used in dental implants, bone grafts, and joint replacements.

Polymers

Polymers are used in biocompatible materials due to their flexibility, versatility, and biodegradability. Examples of biocompatible polymers include polyethylene, polyurethane, and poly(lactic-co-glycolic acid). These polymers are commonly used in drug delivery systems, tissue engineering scaffolds, and artificial organs.

Composites

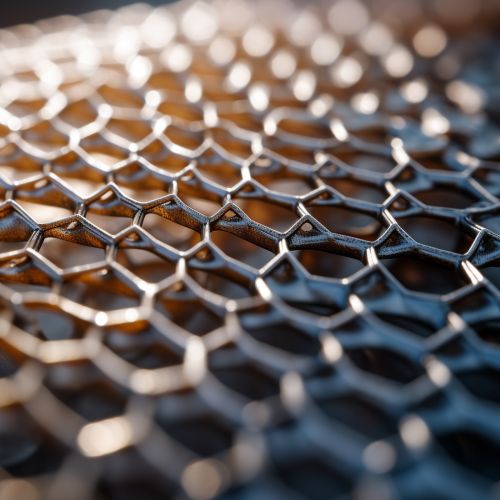

Composites are used in biocompatible materials due to their ability to combine the beneficial properties of different materials. Examples of biocompatible composites include carbon fiber reinforced polymer, bioactive glass, and hydrogel. These composites are commonly used in bone grafts, dental restorations, and wound dressings.

Factors Affecting Biocompatibility

The biocompatibility of a material is influenced by several factors, including its chemical composition, surface properties, mechanical properties, and degradation behavior.

Chemical Composition

The chemical composition of a material can significantly affect its biocompatibility. For example, materials that release toxic substances or cause allergic reactions are not biocompatible. Therefore, it is crucial to select materials with a suitable chemical composition for medical devices and implants.

Surface Properties

The surface properties of a material can also affect its biocompatibility. For example, materials with a rough surface can cause tissue irritation, while materials with a smooth surface can promote tissue integration. Therefore, it is essential to control the surface properties of materials to enhance their biocompatibility.

Mechanical Properties

The mechanical properties of a material can influence its biocompatibility. For example, materials that are too soft may not provide adequate support for tissues, while materials that are too hard may cause tissue damage. Therefore, it is necessary to select materials with appropriate mechanical properties for medical devices and implants.

Degradation Behavior

The degradation behavior of a material can impact its biocompatibility. For example, materials that degrade too quickly may not provide long-term support for tissues, while materials that degrade too slowly may cause chronic inflammation. Therefore, it is crucial to control the degradation behavior of materials to optimize their biocompatibility.

Testing and Evaluation of Biocompatibility

The biocompatibility of a material is typically evaluated through a series of in vitro and in vivo tests. These tests are designed to assess the material's potential to cause adverse biological responses, such as cytotoxicity, genotoxicity, and immunotoxicity.

In Vitro Testing

In vitro testing involves the use of cell cultures to evaluate the biocompatibility of a material. This type of testing can provide valuable information about the material's cytotoxicity, genotoxicity, and immunotoxicity. However, in vitro testing cannot fully replicate the complex biological environment of the human body.

In Vivo Testing

In vivo testing involves the use of animal models to evaluate the biocompatibility of a material. This type of testing can provide more comprehensive information about the material's biological responses, such as tissue integration, inflammation, and degradation. However, in vivo testing is more time-consuming and costly than in vitro testing.

Applications of Biocompatible Materials

Biocompatible materials have a wide range of applications in the medical field. These include orthopedic implants, dental implants, cardiovascular devices, drug delivery systems, tissue engineering scaffolds, and artificial organs.

Orthopedic Implants

Orthopedic implants, such as artificial joints and bone plates, are often made of biocompatible metals, ceramics, or composites. These materials provide the necessary strength and durability for the implants, while also promoting tissue integration and preventing adverse biological responses.

Dental Implants

Dental implants, such as crowns and bridges, are often made of biocompatible metals, ceramics, or polymers. These materials provide the necessary hardness and wear resistance for the implants, while also promoting bone integration and preventing oral infections.

Cardiovascular Devices

Cardiovascular devices, such as heart valves and stents, are often made of biocompatible metals or polymers. These materials provide the necessary flexibility and biocompatibility for the devices, while also preventing thrombosis and inflammation.

Drug Delivery Systems

Drug delivery systems, such as nanoparticles and microspheres, are often made of biocompatible polymers. These materials provide the necessary versatility and biodegradability for the systems, while also controlling the release of drugs and preventing cytotoxicity.

Tissue Engineering Scaffolds

Tissue engineering scaffolds, such as hydrogels and nanofibers, are often made of biocompatible polymers or composites. These materials provide the necessary porosity and bioactivity for the scaffolds, while also promoting cell adhesion and tissue regeneration.

Artificial Organs

Artificial organs, such as heart pumps and kidney dialyzers, are often made of biocompatible metals, ceramics, or polymers. These materials provide the necessary strength and biocompatibility for the organs, while also preventing immunogenicity and biofouling.

Conclusion

Biocompatible materials play a crucial role in the development of safe and effective medical devices and implants. These materials must meet several requirements, including suitable chemical composition, surface properties, mechanical properties, and degradation behavior. The biocompatibility of these materials is typically evaluated through in vitro and in vivo tests, and they have a wide range of applications in the medical field, including orthopedic implants, dental implants, cardiovascular devices, drug delivery systems, tissue engineering scaffolds, and artificial organs.