Advances in Organic Photovoltaics

Introduction

Organic photovoltaics (OPVs) represent a subfield of photovoltaic technology that focuses on the use of organic molecules or polymers for light absorption and charge transport. The primary objective of OPVs is to produce cost-effective, flexible, and lightweight solar cells. The field has seen significant advancements in recent years, with improvements in efficiency, stability, and scalability.

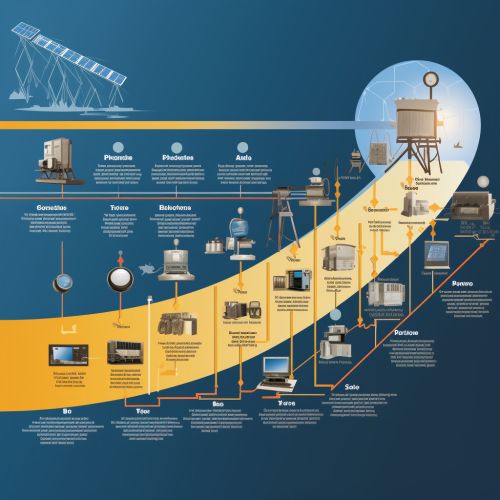

History

The concept of OPVs was first introduced in the 1980s, when researchers began exploring the potential of organic materials in solar cell applications. The first generation of OPVs, based on single-layer devices, had a power conversion efficiency (PCE) of less than 1%. However, the introduction of the bulk heterojunction (BHJ) concept in the 1990s marked a significant milestone in the development of OPVs.

Materials

The choice of materials plays a crucial role in the performance of OPVs. The active layer of an OPV device typically consists of a blend of a donor material and an acceptor material. The donor material is usually a conjugated polymer, while the acceptor is often a fullerene derivative. Recent advancements have seen the emergence of non-fullerene acceptors (NFAs), which have demonstrated superior performance compared to their fullerene counterparts.

Donor Materials

Conjugated polymers, such as poly(3-hexylthiophene) (P3HT) and poly(3,4-ethylenedioxythiophene) (PEDOT), have been widely used as donor materials in OPVs due to their good optical absorption and charge transport properties. Recent advancements have led to the development of new donor materials with improved properties, such as low-bandgap polymers and high-mobility polymers.

Acceptor Materials

Fullerene derivatives, such as [6,6]-phenyl C61 butyric acid methyl ester (PCBM), have been the standard acceptor materials in OPVs for many years. However, their limitations, including poor absorption in the visible range and high production cost, have led to the exploration of alternative acceptor materials. NFAs, such as indacenodithiophene-based acceptors, have shown great promise, offering higher PCEs and better stability than fullerenes.

Device Architecture

The architecture of an OPV device has a significant impact on its performance. The most common architecture is the BHJ, which consists of a blend of donor and acceptor materials in the active layer. This architecture allows for efficient charge separation and transport, leading to higher PCEs.

Single-Layer Devices

The simplest OPV device architecture is the single-layer device, which consists of a single organic layer sandwiched between two electrodes. However, these devices suffer from low PCEs due to inefficient charge separation.

Bilayer Devices

Bilayer devices, which consist of separate donor and acceptor layers, offer improved charge separation compared to single-layer devices. However, their performance is limited by the short exciton diffusion length in organic materials.

Bulk Heterojunction Devices

BHJ devices, which consist of a blend of donor and acceptor materials in the active layer, offer the best performance among OPV architectures. The interpenetrating network of donor and acceptor materials in the BHJ facilitates efficient charge separation and transport, leading to higher PCEs.

Advances in Organic Photovoltaics

Advancements in OPVs have been driven by improvements in materials, device architectures, and fabrication techniques. These advancements have led to significant increases in PCEs, with the highest reported PCE for an OPV device currently exceeding 18%.

Materials Advances

Advancements in materials for OPVs have focused on the development of new donor and acceptor materials with improved properties. The introduction of low-bandgap polymers and high-mobility polymers has led to significant improvements in the performance of OPV devices. Similarly, the emergence of NFAs has provided a viable alternative to fullerenes, offering higher PCEs and better stability.

Device Architecture Advances

Advancements in device architecture for OPVs have focused on optimizing the BHJ structure for efficient charge separation and transport. Techniques such as thermal annealing, solvent annealing, and the use of processing additives have been used to control the morphology of the BHJ, leading to improved device performance.

Fabrication Technique Advances

Advancements in fabrication techniques for OPVs have focused on improving the scalability and reproducibility of the manufacturing process. Techniques such as roll-to-roll printing and slot-die coating have been developed for large-scale production of OPVs, while advanced characterization techniques have been used to ensure the quality and consistency of the devices.

Future Prospects

The future of OPVs looks promising, with ongoing research focusing on further improving the efficiency, stability, and scalability of the technology. The development of new materials, the optimization of device architectures, and the refinement of fabrication techniques are expected to drive further advancements in the field.