Thermoelectric Cooler/

Introduction

A thermoelectric cooler (TEC), also known as a Peltier cooler, is a solid-state active heat pump that transfers heat from one side of the device to the other, with consumption of electrical energy, depending on the direction of the current. TECs are used for applications where precise temperature control is required, such as in electronic devices, laboratory instruments, and portable coolers.

Principle of Operation

The operation of a thermoelectric cooler is based on the Peltier effect, which was discovered by Jean Charles Athanase Peltier in 1834. When an electric current flows through a circuit of two different conductors, heat is absorbed at one junction and released at the other. This effect is the basis for thermoelectric cooling.

The Peltier effect is closely related to the Seebeck effect, where a temperature difference between two dissimilar conductors or semiconductors generates a voltage. Both effects are manifestations of the same physical principles, and together with the Thomson effect, they form the basis of thermoelectric phenomena.

Construction and Materials

Thermoelectric coolers are typically constructed from semiconductor materials, such as bismuth telluride (Bi2Te3), which have high thermoelectric efficiency. The device consists of an array of thermocouples connected electrically in series and thermally in parallel. Each thermocouple is made of n-type and p-type semiconductor elements, which are joined by metallic interconnects.

The choice of materials is crucial for the performance of TECs. The figure of merit (ZT) is a dimensionless parameter that measures the efficiency of a thermoelectric material. It is defined as ZT = (S^2σT)/κ, where S is the Seebeck coefficient, σ is the electrical conductivity, T is the absolute temperature, and κ is the thermal conductivity. High-performance thermoelectric materials have a high Seebeck coefficient, high electrical conductivity, and low thermal conductivity.

Applications

Thermoelectric coolers have a wide range of applications due to their ability to provide precise temperature control. Some of the key applications include:

Electronics Cooling

TECs are used to cool electronic components, such as microprocessors, graphic cards, and laser diodes, where overheating can lead to performance degradation or failure. The ability to maintain a stable temperature is critical for the reliability and longevity of these components.

Laboratory Instruments

In laboratory settings, TECs are used in instruments that require precise temperature control, such as spectrophotometers, chromatographs, and thermal cyclers. These instruments often require stable temperatures to ensure accurate and reproducible results.

Portable Coolers

Thermoelectric coolers are commonly used in portable coolers and refrigerators, where they provide a compact and reliable means of cooling without the need for refrigerants. These devices are popular for camping, picnics, and other outdoor activities.

Advantages and Disadvantages

Advantages

Thermoelectric coolers offer several advantages over traditional cooling methods:

- **No Moving Parts:** TECs are solid-state devices with no moving parts, which makes them highly reliable and maintenance-free.

- **Compact Size:** TECs are small and lightweight, making them suitable for applications with space constraints.

- **Precise Temperature Control:** TECs can provide precise temperature control with rapid response times.

- **Environmentally Friendly:** TECs do not use refrigerants, which can be harmful to the environment.

Disadvantages

Despite their advantages, TECs also have some limitations:

- **Limited Cooling Capacity:** TECs have a lower cooling capacity compared to traditional refrigeration systems, which limits their use in high-power applications.

- **Efficiency:** The efficiency of TECs is generally lower than that of conventional cooling systems, leading to higher power consumption.

- **Cost:** The materials used in TECs, such as bismuth telluride, can be expensive, which increases the overall cost of the device.

Performance Optimization

The performance of a thermoelectric cooler can be optimized by considering several factors:

Material Selection

The choice of thermoelectric materials is critical for optimizing performance. Researchers are continually developing new materials with higher figures of merit (ZT) to improve the efficiency of TECs. Advanced materials, such as skutterudites, clathrates, and half-Heusler compounds, are being explored for their potential to enhance thermoelectric performance.

Device Design

The design of the thermoelectric cooler, including the arrangement of thermocouples and the quality of the interconnects, plays a significant role in its performance. Optimizing the geometry and minimizing thermal and electrical contact resistances can improve the overall efficiency of the device.

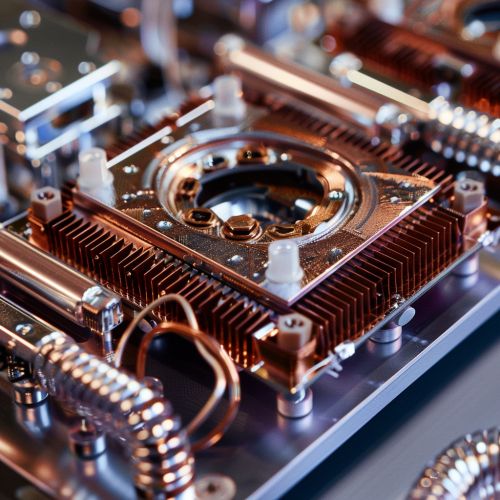

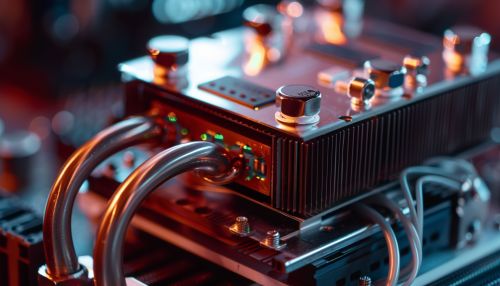

Heat Dissipation

Efficient heat dissipation is essential for the performance of TECs. The hot side of the TEC must be effectively cooled to maintain a temperature gradient across the device. This can be achieved using heat sinks, fans, or liquid cooling systems.

Future Developments

The field of thermoelectric cooling is continually evolving, with ongoing research focused on improving the efficiency and performance of TECs. Some of the key areas of development include:

Nanostructured Materials

Nanostructuring is a promising approach to enhance the thermoelectric properties of materials. By engineering materials at the nanoscale, researchers can reduce thermal conductivity while maintaining or improving electrical conductivity and the Seebeck coefficient. This can lead to higher figures of merit (ZT) and more efficient TECs.

Hybrid Systems

Hybrid cooling systems that combine thermoelectric coolers with other cooling technologies, such as vapor-compression refrigeration, are being explored to leverage the advantages of both methods. These systems can provide higher cooling capacities and improved efficiency.

Advanced Manufacturing Techniques

Advances in manufacturing techniques, such as additive manufacturing and precision machining, are enabling the production of more complex and efficient thermoelectric devices. These techniques allow for greater design flexibility and the ability to create custom TECs for specific applications.