Solid lipid nanoparticle: Difference between revisions

(Created page with "== Introduction == Solid lipid nanoparticles (SLNs) are a class of nanoparticles composed of solid lipids. They are utilized in various fields, including pharmaceuticals, cosmetics, and nutraceuticals, due to their unique properties such as controlled drug release, enhanced bioavailability, and biocompatibility. SLNs are an alternative to traditional colloidal carriers like liposomes, emulsions, and polymeric nanoparticles. == Composition == SLNs are primarily composed...") |

No edit summary |

||

| Line 69: | Line 69: | ||

<references /> | <references /> | ||

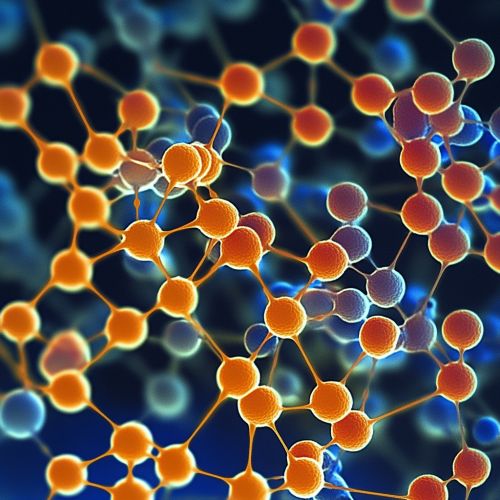

[[Image:Detail-97957.jpg|thumb|center|High-resolution image of solid lipid nanoparticles under an electron microscope.|class=only_on_mobile]] | |||

[[Image:Detail-97958.jpg|thumb|center|High-resolution image of solid lipid nanoparticles under an electron microscope.|class=only_on_desktop]] | |||

Latest revision as of 04:53, 13 September 2024

Introduction

Solid lipid nanoparticles (SLNs) are a class of nanoparticles composed of solid lipids. They are utilized in various fields, including pharmaceuticals, cosmetics, and nutraceuticals, due to their unique properties such as controlled drug release, enhanced bioavailability, and biocompatibility. SLNs are an alternative to traditional colloidal carriers like liposomes, emulsions, and polymeric nanoparticles.

Composition

SLNs are primarily composed of lipids that remain solid at room and body temperature. These lipids can be triglycerides, fatty acids, steroids, or waxes. The lipid matrix is stabilized by surfactants, which can be ionic or non-ionic. Commonly used surfactants include Tween 80, soy lecithin, and Pluronic F68.

Preparation Methods

Several methods are employed to prepare SLNs, each with its advantages and limitations:

High-Pressure Homogenization

High-pressure homogenization (HPH) is a widely used technique for SLN production. It involves forcing the lipid phase through a narrow gap at high pressure, resulting in the formation of nanoparticles. HPH can be performed at elevated temperatures (hot HPH) or room temperature (cold HPH).

Solvent Evaporation

In the solvent evaporation method, the lipid is dissolved in a water-immiscible organic solvent. The solution is then emulsified in an aqueous phase containing a surfactant. The organic solvent is evaporated under reduced pressure, leading to the formation of SLNs.

Microemulsion Technique

Microemulsions are clear, thermodynamically stable mixtures of oil, water, and surfactant. In the microemulsion technique, the lipid phase is mixed with a surfactant and co-surfactant to form a microemulsion, which is then dispersed in cold water, leading to the formation of SLNs.

Characterization

The characterization of SLNs is crucial to ensure their quality and efficacy. Key parameters include:

Particle Size and Distribution

The size and distribution of SLNs can be determined using techniques such as dynamic light scattering (DLS) and laser diffraction. The particle size typically ranges from 50 to 1000 nm.

Zeta Potential

Zeta potential is a measure of the surface charge of nanoparticles and is indicative of their stability. A high zeta potential (positive or negative) usually implies good stability due to electrostatic repulsion between particles.

Morphology

The morphology of SLNs can be examined using electron microscopy techniques such as transmission electron microscopy (TEM) and scanning electron microscopy (SEM). These techniques provide detailed images of the nanoparticle surface and structure.

Encapsulation Efficiency

Encapsulation efficiency refers to the percentage of the active ingredient encapsulated within the SLNs. It can be determined using techniques such as high-performance liquid chromatography (HPLC) or ultraviolet-visible spectroscopy (UV-Vis).

Applications

SLNs have a wide range of applications due to their unique properties:

Drug Delivery

SLNs are extensively used in drug delivery systems. They offer controlled and sustained release of drugs, improved bioavailability, and reduced toxicity. SLNs can encapsulate both hydrophilic and hydrophobic drugs, making them versatile carriers.

Cosmetics

In the cosmetic industry, SLNs are used in formulations for skin care, hair care, and sun protection. They provide enhanced stability of active ingredients, controlled release, and improved skin penetration.

Nutraceuticals

SLNs are also employed in the delivery of nutraceuticals, which are products derived from food sources with extra health benefits. They enhance the bioavailability and stability of nutraceuticals, making them more effective.

Advantages and Limitations

Advantages

- Biocompatibility and biodegradability. - Controlled and sustained drug release. - Protection of encapsulated drugs from degradation. - Enhanced bioavailability of poorly water-soluble drugs.

Limitations

- Potential for drug expulsion during storage. - Limited drug loading capacity. - Possible cytotoxicity of surfactants used in formulations.

Future Perspectives

The field of SLNs is rapidly evolving, with ongoing research focused on improving their properties and expanding their applications. Advances in lipid materials, surfactants, and preparation techniques are expected to enhance the performance of SLNs. Additionally, the development of targeted SLNs for specific diseases and conditions holds great promise for personalized medicine.

See Also

References