Otto cycle: Difference between revisions

(Created page with "== Introduction == The Otto cycle is a thermodynamic cycle that describes the functioning of a typical spark-ignition internal combustion engine. Named after Nikolaus Otto, who is credited with developing the first practical four-stroke engine, the Otto cycle is fundamental to the operation of gasoline engines. This cycle is characterized by four distinct processes: two isentropic (adiabatic) processes and two isochoric (constant volume) processes. == Therm...") |

No edit summary |

||

| Line 69: | Line 69: | ||

* [[Thermodynamics]] | * [[Thermodynamics]] | ||

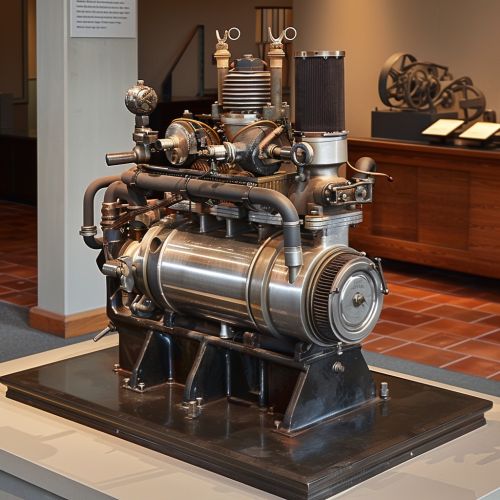

[[Image:Detail-92189.jpg|thumb|center|Photograph of a historical Otto engine on display in a museum.|class=only_on_mobile]] | |||

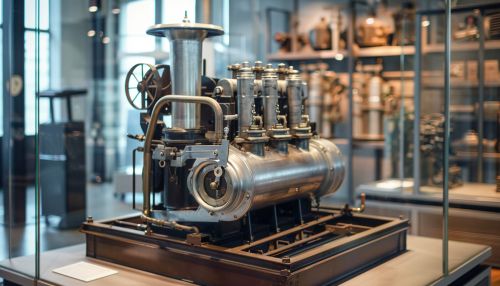

[[Image:Detail-92190.jpg|thumb|center|Photograph of a historical Otto engine on display in a museum.|class=only_on_desktop]] | |||

== Categories == | == Categories == | ||

Latest revision as of 19:21, 17 June 2024

Introduction

The Otto cycle is a thermodynamic cycle that describes the functioning of a typical spark-ignition internal combustion engine. Named after Nikolaus Otto, who is credited with developing the first practical four-stroke engine, the Otto cycle is fundamental to the operation of gasoline engines. This cycle is characterized by four distinct processes: two isentropic (adiabatic) processes and two isochoric (constant volume) processes.

Thermodynamic Processes

The Otto cycle consists of four primary thermodynamic processes:

1. Isentropic Compression

During the isentropic compression phase, the piston moves from the bottom dead center (BDC) to the top dead center (TDC), compressing the air-fuel mixture in the cylinder. This process is adiabatic, meaning no heat is transferred to or from the working fluid. The pressure and temperature of the mixture increase significantly due to the reduction in volume.

2. Isochoric Heat Addition

At the end of the compression stroke, the spark plug ignites the compressed air-fuel mixture, causing a rapid increase in temperature and pressure while the volume remains constant. This is the isochoric heat addition phase, where the energy from the fuel is converted into thermal energy.

3. Isentropic Expansion

The high-pressure, high-temperature gases then expand adiabatically, pushing the piston from TDC back to BDC. This is the power stroke, where the thermal energy is converted into mechanical work. The pressure and temperature of the gases decrease as the volume increases.

4. Isochoric Heat Rejection

Finally, the exhaust valve opens, and the remaining gases are expelled from the cylinder at constant volume. This is the isochoric heat rejection phase, where the cycle returns to its initial state, ready to begin again.

Mathematical Analysis

The efficiency of the Otto cycle can be derived from the thermodynamic properties of the working fluid. The thermal efficiency (\(\eta\)) of the Otto cycle is given by:

\[ \eta = 1 - \left( \frac{1}{r^{\gamma-1}} \right) \]

where \(r\) is the compression ratio and \(\gamma\) (gamma) is the specific heat ratio (Cp/Cv) of the working fluid. The compression ratio is defined as the ratio of the total cylinder volume when the piston is at BDC to the clearance volume when the piston is at TDC.

Practical Considerations

In real engines, several factors affect the idealized efficiency of the Otto cycle:

Combustion Efficiency

The actual combustion process is not instantaneous and complete as assumed in the ideal cycle. Factors such as fuel type, air-fuel ratio, and engine design influence combustion efficiency.

Heat Losses

In practice, some heat is lost to the engine components and surroundings, reducing the overall efficiency. This heat loss occurs during both the compression and expansion strokes.

Friction Losses

Mechanical friction between moving parts, such as the piston, crankshaft, and valves, also reduces the efficiency of real engines compared to the ideal Otto cycle.

Applications

The Otto cycle is predominantly used in automobiles, motorcycles, and small engines. It is favored for its simplicity, reliability, and ability to deliver high power output relative to engine size. Modern advancements, such as turbocharging and direct fuel injection, have further enhanced the performance and efficiency of Otto cycle engines.

Historical Development

Nikolaus Otto's development of the four-stroke engine in the late 19th century marked a significant milestone in the history of internal combustion engines. His work laid the foundation for the widespread adoption of gasoline engines in transportation and industry. Otto's engine was the first to successfully implement the four-stroke cycle, leading to more efficient and powerful engines.

Future Trends

The future of Otto cycle engines lies in improving efficiency and reducing emissions. Innovations such as variable valve timing, advanced ignition systems, and hybridization are being explored to enhance the performance of Otto cycle engines. Additionally, alternative fuels like ethanol and hydrogen are being considered to reduce the environmental impact of these engines.

See Also